3 methods for correct coloring of industrial aluminum profiles

by:Zeyi

2021-07-28

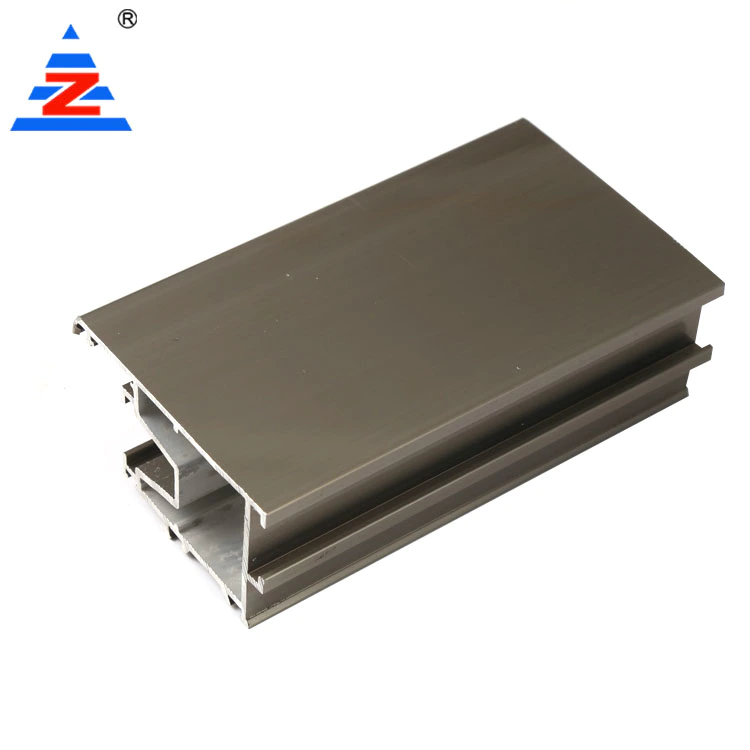

Good quality aluminum profiles are all colored. Coloring can not only improve the aesthetics of the aluminum, but also improve the corrosion resistance of the aluminum surface. Do you know what are the methods for coloring aluminum? Let me introduce you. 1. Pretreatment: Cleaning the surface of aluminum profiles by chemical or physical methods can show the original color of aluminum profiles. We can also obtain mirror or matte aluminum profile surfaces through mechanical means. 2. After the surface treatment of the anodized aluminum profile, under certain processing conditions, the surface of the aluminum material is anodized, and the oxidized aluminum surface will form a porous and strong adsorption protective film. 3. Sealing The porous oxide film formed after anodic oxidation is sealed to improve the corrosion resistance of aluminum. We can use the strong adsorption of the oxide film before sealing to adsorb and deposit some metal salts in the film pores. Let the aluminum profile show a color other than the natural color. The above are three methods of coloring aluminum profiles. If you don't know anything, you can consult the editor.

Zeyi allocates customer service resources to the platform where their customers are most vocal.

For good quality aluminum window profile manufacturers and a good variety of products to choose from, visit Zeyi Aluminum Co., Ltd. at Zeyi Aluminum Profiles.

custom aluminium extrusion is attracting a great positive feedback from the customers. And many of our clients are fully satisfied with it.

Basically, you cannot have a aluminum extrusion rail without having the right custom aluminium extrusion. Since you are going to use it regularly, be sure to invest in one that has a high quality.

We sells custom aluminium extrusion and focus on operational procedure and manufacturing facilities aluminum window profile manufacturers.

Zeyi allocates customer service resources to the platform where their customers are most vocal.

For good quality aluminum window profile manufacturers and a good variety of products to choose from, visit Zeyi Aluminum Co., Ltd. at Zeyi Aluminum Profiles.

custom aluminium extrusion is attracting a great positive feedback from the customers. And many of our clients are fully satisfied with it.

Basically, you cannot have a aluminum extrusion rail without having the right custom aluminium extrusion. Since you are going to use it regularly, be sure to invest in one that has a high quality.

We sells custom aluminium extrusion and focus on operational procedure and manufacturing facilities aluminum window profile manufacturers.

Custom message