About the construction process of industrial aluminum powder spraying

by:Zeyi

2021-05-11

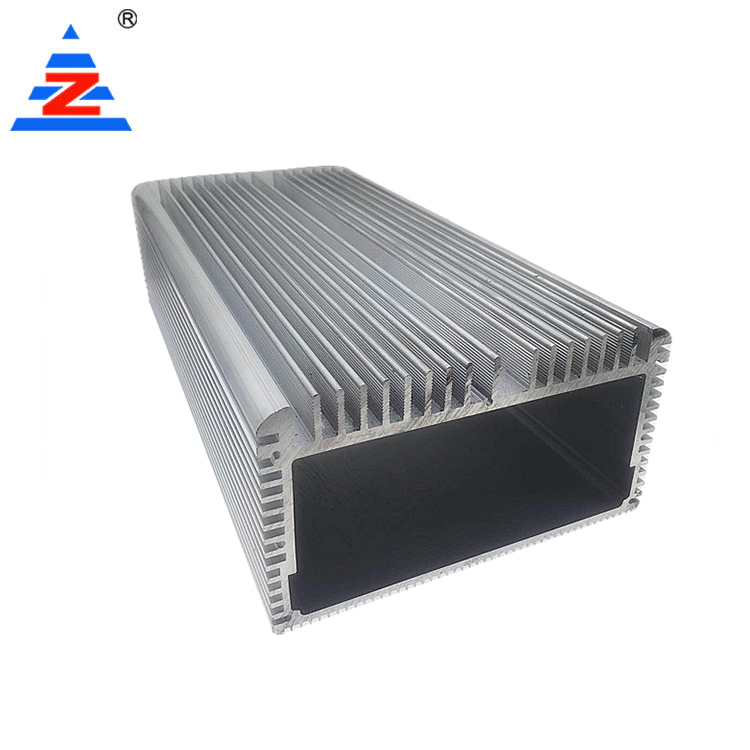

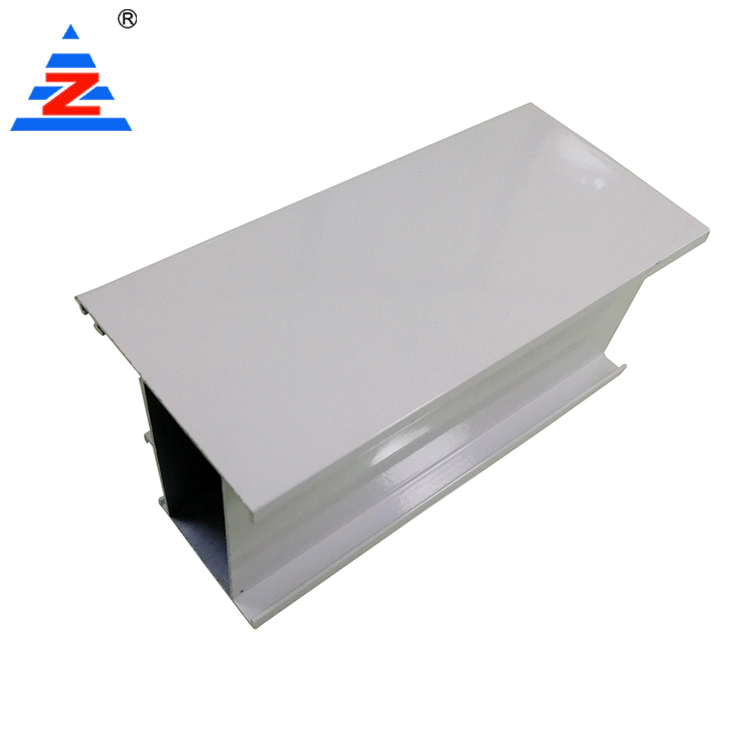

powder spraying construction process: The so-called powder electrostatic spraying is the principle of using high-voltage electrostatic corona electric field. A high voltage negative electrode is connected to the metal guide mark on the head of the spray gun, and the sprayed workpiece is grounded to form a positive electrode, so that a strong electrostatic electric field is formed between the spray gun and the workpiece. When the compressed air used as the carrier gas sends the powder coating from the powder supply tank to the guide rod of the spray gun through the powder tube, the corona discharge generated by the guide rod connected to the high voltage negative electrode generates a dense negative charge nearby. , So that the powder is negatively charged and enters the electrostatic field with high electric field strength. Under the dual action of electrostatic force and carrier gas, the powder uniformly flies to the surface of the grounded workpiece to form a uniform layer of powder, which is then heated and solidified to transform into Durable coating film. 1. The industrial aluminum profile powder spraying process is relatively simple, mainly due to the improvement of the automatic accuracy of the main equipment in the production process, and the microcomputer control of some main technical parameters can be realized, which effectively reduces the difficulty of process operation, and the auxiliary equipment is greatly improved. 2. The yield rate is high. Under normal circumstances, if the various measures are appropriate, the production of unqualified products can be controlled to the greatest extent; 3. The energy consumption is significantly reduced. In the production process of ordinary anodizing and electrophoretic coating, The consumption of water and electricity is quite large, especially in the oxidation process. The output current of the rectifier can reach between 8000~11000A, and the voltage is between 15~17.5V. In addition to the heat consumption of the machine itself, it is necessary to continuously use circulating water to cool down, and the electricity consumption per ton is often about 1000 degrees. At the same time, the reduction of auxiliary facilities can also reduce some power consumption; 4. Reduce the pollution of water and air, and no longer use caustic soda, sulfuric acid and other liquid organic solvents, reduce water and air pollution, and effectively improve aluminum profiles and The competitive strength of plastic steel profiles as environmentally friendly products has correspondingly reduced some production costs; 5. The labor intensity of workers has been significantly reduced. Due to the use of automated assembly line operations, the feeding method and the use of fixtures have been significantly simplified, which improves production efficiency , It also reduces labor intensity; 6. The surface quality requirements of the aluminum profile after processing have been significantly reduced. The powder coating can completely cover the extrusion lines on the surface of the profile, conceal some of the defects on the surface of the aluminum profile, and improve the processing of the aluminum profile. The surface quality of the finished product; 7 Some physical indexes of the industrial aluminum profile coating film are significantly improved compared with other surface treatment films, such as hardness and wear resistance, which can effectively extend the service life of aluminum profiles. ————The article comes from the Internet. If there is any infringement, please contact to delete it.

The point for Zeyi Aluminum Co., Ltd. is that managerial processes are as important as other inputs in production and can create significant competitive advantage.

Dazzle your next event with aluminum extrusion rail custom aluminium extrusion and to buy best product, only trust Zeyi Aluminum Co., Ltd..

Utilizing high technology to manufacture products can afford a fully experience to customers by using custom aluminium extrusion.

Zeyi Aluminum Co., Ltd. has unique staffs who will serve you with their best ideas by affording you with high-quality service.

custom aluminium extrusion allows users to apply in different ways for satisfying their needs.

The point for Zeyi Aluminum Co., Ltd. is that managerial processes are as important as other inputs in production and can create significant competitive advantage.

Dazzle your next event with aluminum extrusion rail custom aluminium extrusion and to buy best product, only trust Zeyi Aluminum Co., Ltd..

Utilizing high technology to manufacture products can afford a fully experience to customers by using custom aluminium extrusion.

Zeyi Aluminum Co., Ltd. has unique staffs who will serve you with their best ideas by affording you with high-quality service.

custom aluminium extrusion allows users to apply in different ways for satisfying their needs.

Custom message