Aluminum profile extrusion, classification and use

by:Zeyi

2021-07-08

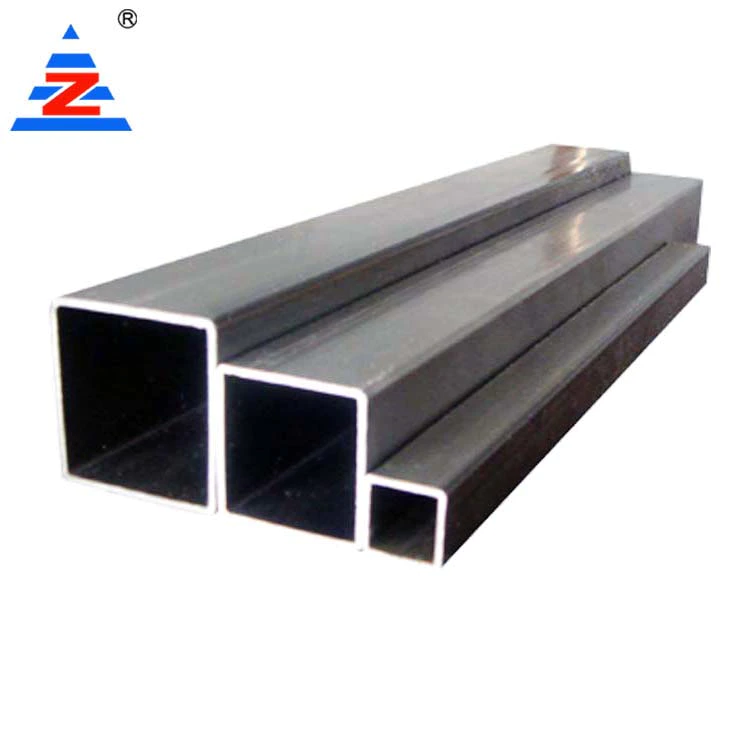

The aluminum extrusion press is composed of a machine base, a front column frame, a tension column, an extrusion cylinder, and a hydraulic system under electrical control. It is also equipped with a mold base, thimble, scale plate, slide plate, etc. Aluminum profile extrusion is a plastic processing method that applies external force to the metal blank placed in the container (extrusion cylinder) to make it flow out of a specific die hole to obtain the desired cross-sectional shape and size. The classification of aluminum extrusion methods is based on the type of metal in the aluminum extrusion cylinder, the state of stress and strain, the extrusion direction of the aluminum extrusion, the lubrication state, the extrusion temperature, the extrusion speed, the type or structure of the mold, and the shape of the blank Or the number, the shape or number of products, etc., can be divided into forward extrusion method, reverse extrusion method, (including plane deformation extrusion, axisymmetric deformation extrusion, general three-dimensional deformation extrusion) lateral extrusion Pressing method, glass lubricating extrusion method, hydrostatic extrusion method, continuous extrusion method, etc. Here to talk about it for everyone: the positive thermal deformation extrusion method. The vast majority of hot-deformed aluminum production companies use the positive hot-deformation extrusion method to obtain aluminum with the required cross-sectional shape through specific molds (flat molds, cone molds, and split molds). The forward extrusion process is simple, the equipment requirements are not high, the metal deformability is high, the production range is wide, the aluminum material performance is controllable, the production flexibility is large, and the tool and die are easy to maintain and modify. The defect is that the inner surface of the extrusion cylinder has strong friction with the aluminum material, which accounts for a large proportion of the extrusion energy consumption. The friction is easy to cause the ingot in the cylinder to heat up and increase the instability of the profile, damage the efficiency of the finished product, and limit the aluminum and aluminum The extrusion speed of the alloy accelerates the abrasion and service life of the extrusion die, and the structure and properties of the product are uneven before and after. Types, performance and usage of hot-deformed aluminum alloys Types of hot-deformed aluminum alloys are divided into 8 categories according to performance and usage requirements, with different performances and uses. 1. Pure aluminum (L series) corresponds to the international brand 1000 series pure aluminum industrial pure aluminum, excellent processability, corrosion resistance, surface treatment and conductivity, but low strength, used in household products, electrical products, medicine And food packaging, power transmission and distribution materials, etc. 2, duralumin (Ly) corresponds to the international brand 2000AL-Cu (aluminum copper) alloy. Apply to large components and brackets, with high Cu content and poor corrosion resistance. 3. Anti-rust aluminum (LF) corresponds to the international brand 3000AL-Mn (aluminum manganese) alloy. Heat treatment can not be strengthened, processability, corrosion resistance is equivalent to pure aluminum, the strength has been improved, and the welding performance is good. It is widely used in daily necessities, building materials, devices, etc. 4. Special aluminum (LT) corresponds to the international grade 4000AL-Si (aluminum silicon) alloy. mainly welding materials, low melting point (575-630 degrees), good fluidity and other characteristics. 5. Anti-rust aluminum (LF) corresponds to the international brand 5000AL-Mg (aluminum-magnesium) alloy. Heat treatment cannot be strengthened, corrosion resistance, weldability, and surface gloss are excellent. By controlling the content of Mg, alloys with different strength levels can be obtained. Less used for decoration materials, advanced devices. Used in ships, vehicles, and building materials. Highly used for welding components in ships and vehicle chemical plants. 6. 6000AL-Mg-Si series alloy Mg2Si precipitation hardening heat treatment can strengthen the alloy, with good corrosion resistance, medium strength, and excellent hot workability. Therefore, it is widely used as an extrusion material and has good forming properties. Higher hardness can be obtained by quenching . It is widely used in building profiles and is also the most important source of materials in industry. 7. Ultra-hard aluminum (LC) corresponds to the international brand 7000AL-Zn-Mg-Cu (aluminum zinc magnesium copper) high-strength aluminum alloy and AL-Zn-Mg alloy for welding components, two types of high strength, excellent welding and quenching performance , The disadvantage is that the stress corrosion cracking resistance is poor, and proper heat treatment is needed to improve it. The former is mainly used for aircraft and sporting goods, and the latter is mainly used for welding structural materials for railway vehicles. 8, 8000 (AL-LI) aluminum-lithium alloy The biggest feature is that the density is lower than 7000 series 8%-9%, high rigidity, high strength, light weight, mainly used in aircraft, missiles, engines and other military applications.

At a time when technology is essential for custom aluminium extrusion, ensuring that it works in a symbiotic way with your human employees is key.

Our vision serves as the framework for our custom aluminium extrusion and guides every aspect of our business by describing what we need to accomplish in order to continue achieving sustainable, quality growth.

With innovative technology, our professionals can spend more time focused on strategies that will improve custom aluminium extrusion’s quality and deliver a more positive customers experience.

Zeyi Aluminum Co., Ltd. provides professional , technology and human expertise clients need to find trusted answers. Go to Zeyi Aluminum Profiles for answers.

Simultaneously being able to offer not only the product but also the service, gives the customer a quality 'one-stop-shop' service.

At a time when technology is essential for custom aluminium extrusion, ensuring that it works in a symbiotic way with your human employees is key.

Our vision serves as the framework for our custom aluminium extrusion and guides every aspect of our business by describing what we need to accomplish in order to continue achieving sustainable, quality growth.

With innovative technology, our professionals can spend more time focused on strategies that will improve custom aluminium extrusion’s quality and deliver a more positive customers experience.

Zeyi Aluminum Co., Ltd. provides professional , technology and human expertise clients need to find trusted answers. Go to Zeyi Aluminum Profiles for answers.

Simultaneously being able to offer not only the product but also the service, gives the customer a quality 'one-stop-shop' service.

Custom message