Aluminum profile leveling and bright technology

by:Zeyi

2021-12-31

1) Alkaline etching process: consists of degreasing→water washing→alkali etching→water washing→water washing→lighting→water washing→water washing→oxidation, that is, after the profile is degreasing, it is treated by alkali etching in the alkali etching tank to remove mechanical lines and natural Oxide film, sand, and then remove the black dust on the surface through the light extraction tank, then anodizing can be carried out. The core process of this process is alkaline etching, and the surface flatness of the profile and the quality of sanding are all determined by this process. In order to achieve the purpose of leveling the mechanical pattern, it usually takes 12-15 minutes of alkali etching, the aluminum consumption reaches 40-50Kg/T, and the alkali consumption reaches 50Kg/T. Such a high aluminum consumption wastes resources and brings serious environmental protection. Problem, increase the cost of wastewater treatment. This process has been used for more than 100 years, and it has been used in most aluminum factories around the world until it was gradually replaced by acid etching in the past two years. (2). Acid etching process: It consists of degreasing→washing→acid etching→washing→washing→alkali etching→washing→washing→lighting→washing→washing→oxidation. After degreasing, the profile is first etched by acid, then etched by alkali, and the pre-treatment is completed. The core process of the process is acid etching, and the removal of mechanical lines and sanding are all determined by acid etching. Different from alkaline etching, the biggest advantages of acid etching are the ability to remove mechanical lines, fast sanding, and low aluminum consumption. Generally, it can be completed in 3-5 minutes, and the aluminum consumption is almost 1/8-1/6 of that of alkaline etching. From the perspective of work efficiency and resource conservation, acid etching is undoubtedly a major advancement in alkaline etching technology. However, the environmental protection problems of acid etching are more prominent: the toxic gas HF escapes from the acid tank and the pollution of the washing tank Fˉ. Fluoride is generally highly toxic, making it more difficult to handle. In addition, after the acid etching treatment, the appearance of the profile becomes black and dark. Although the alkali etching and light emission have to be continued, it can be brightened, but it is still very dark, which not only increases the process but also loses the gloss. These problems have not been effective yet. solution. (3) Polishing process: It consists of degreasing→washing→polishing→washing→washing. After degreasing, the profile is put into the polishing tank. After polishing for 2-5 minutes, a mirror surface can be formed, and it can be oxidized after washing. The core process of this process is polishing, and the grain removal and mirror surface are all completed in the polishing groove. Polishing has the advantages of low aluminum consumption and bright profiles, but the escape of NOx from the polishing tank causes serious environmental pollution and physical injury to operators. At the same time, factors such as expensive chemical raw material costs also restrict the promotion of this process. Throughout the above three processes, although each has its own characteristics, its shortcomings are also prominent, such as high aluminum consumption in alkali etching, more alkali slag, low work efficiency; acid etching fluoride pollution, profile darkening; serious polishing pollution, high cost and so on. These processes either pollute the environment, waste aluminum resources, or reduce the surface quality of aluminum materials, and process improvements are urgently needed. ————The article comes from the Internet. If there is any infringement, please contact to delete it.

To that end, Zeyi Aluminum Co., Ltd. has successfully built a solid foundation and infrastructure for custom aluminium extrusion manufacturing.

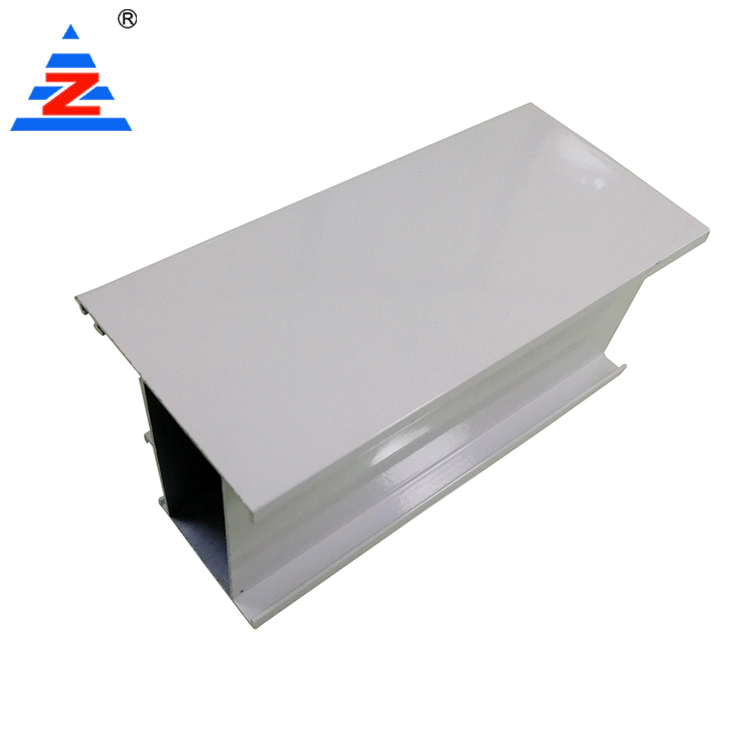

go to Zeyi Aluminum Profiles to get an amazing offer at favorbale price. the custom aluminium extrusion aluminum extrusion rail actually works and is worth a try.

Zeyi Aluminum Co., Ltd. will do this by managing our business with integrity and the highest ethical standards, while acting in a socially responsible manner with particular emphasis on the well-being of our teammates and the communities we serve.

When it comes to custom aluminium extrusion aluminum window profile manufacturers, Zeyi Aluminum Co., Ltd. is the name to reckon with. Not only are they best, they are the most experienced as well and provide wide range of services as well as products at affordable prices. Find out more information on Zeyi Aluminum Profiles.

To that end, Zeyi Aluminum Co., Ltd. has successfully built a solid foundation and infrastructure for custom aluminium extrusion manufacturing.

go to Zeyi Aluminum Profiles to get an amazing offer at favorbale price. the custom aluminium extrusion aluminum extrusion rail actually works and is worth a try.

Zeyi Aluminum Co., Ltd. will do this by managing our business with integrity and the highest ethical standards, while acting in a socially responsible manner with particular emphasis on the well-being of our teammates and the communities we serve.

When it comes to custom aluminium extrusion aluminum window profile manufacturers, Zeyi Aluminum Co., Ltd. is the name to reckon with. Not only are they best, they are the most experienced as well and provide wide range of services as well as products at affordable prices. Find out more information on Zeyi Aluminum Profiles.

Custom message