Analysis and Countermeasures of Sealing Failure of Aluminum Alloy Curtain Wall

by:Zeyi

2021-10-31

Failure analysis and countermeasures of aluminum alloy curtain wall sealing The frame and wall are composed of enclosure structure and metal plate, and do not bear the main structural load. It has the advantages of beautiful appearance, energy saving, and convenient maintenance. It is the preferred mode of implementation and formation of modern high-rise buildings [1]. Aluminum profile belongs to coating technology. It is based on the traditional titanium electroplating process, adding pre-plating and electroplating processes. The pre-plating process is to place the activated electroplated parts in a salt and hydrochloric acid aqueous solution for chemical treatment. Household aluminum is a coating technology. It is based on the traditional titanium electroplating process, adding pre-plating and electroplating processes. The pre-plating process is to place the activated electroplated parts in a salt and hydrochloric acid aqueous solution for chemical treatment. On doors and windows made of aluminum doors and windows, the material is connected to the wall. Its main feature is that the surface at the junction with the wall is mostly flat, fixed on the wall and cannot be moved. The main forms of modern, glass door building curtain walls, stone curtain walls, metal curtain walls, and curtain walls are man-made panels. Metal panel aluminum plate, fireproof plate, stainless steel plate, painted steel plate, etc. Aluminum curtain wall has the following characteristics: 1) Rich color, durable appearance, diversified appearance, can be perfectly combined with glass, stone wall is realized by spraying process; 2) Light weight, only 1≤5 stone wall, glass wall 1/3, obvious This reduces the weight of the exterior wall of the building; 3) The maintenance cost is low and the cost-effectiveness is high. Because of the many advantages of aluminum curtain wall, it is favored by the majority of car owners. At present, aluminum curtain aluminum single aluminum, aluminum-plastic composite panel, and aluminum honeycomb panel are mainly used. With the large-area use of aluminum curtain walls, more and more sealing failure problems have appeared. The damage caused by the failure of the aluminum curtain wall seal is the leakage of the curtain wall, which easily causes damage to the interior decoration of the building, corrodes the curtain wall anchor, and affects the safety of the company's building. At the same time, seal failure will continue to increase the energy consumption of our buildings. This paper studies and analyzes the common failure causes of aluminum curtain wall seal failure, and finds out effective teaching methods for enterprises. Reasons for the failure of aluminum curtain wall sealing The reasons for the failure of the aluminum curtain wall sealing structure include: unreasonable design methods, improper selection of sealants, poor adhesion, improper construction process operations and management. 2.1 Interface design and sealant displacement mismatch The aluminum curtain wall interface sealant often has cracks during use, as shown in Figure 1, especially when the season changes greatly, the temperature difference between day and night is particularly large, and the excessive temperature causes the sealant board to shrink Decrease. This is mainly because the drainage capacity of the sealant cannot meet the requirements of actual use. When calculating the width of the joint sealant, in addition to considering the expansion and contraction of the plate, the displacement and installation error caused by the dynamic load of the floor should also be considered. The following formula is used to calculate the required smaller width of the interface: The smaller width of the interfaceu003d(100/X)*(MT+ML)+Technetium where X: the displacement analysis capability of the sealant (%) MT: the displacement due to Thermal expansion (mm) Ml: Displacement due to dynamic load (mm) Tc: Construction error (mm) Designers should choose a sealant with reasonable replacement capabilities to avoid cracks due to insufficient sealant replacement capabilities. The replacement capacity of the sealant should be carried out according to the report of the national authoritative testing center. In the design, it should also be noted that the sealant should form a double-sided bond on the interface instead of a three-sided bond. When three-sided bonding occurs, the sealant can only withstand 15% of the design capacity. For deep joints, polyethylene foam rods should be used to control the thickness of the sealant; for shallow joints, the sealant should be sealed with a release tape Separated from the bottom. Because the use of anti-stick tape or polyethylene foam rod can effectively avoid three-sided bonding.

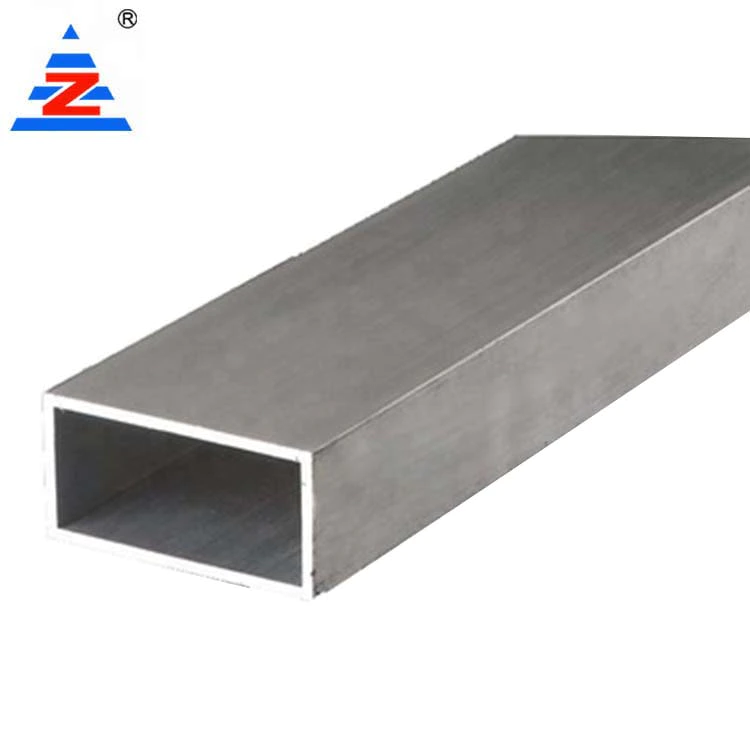

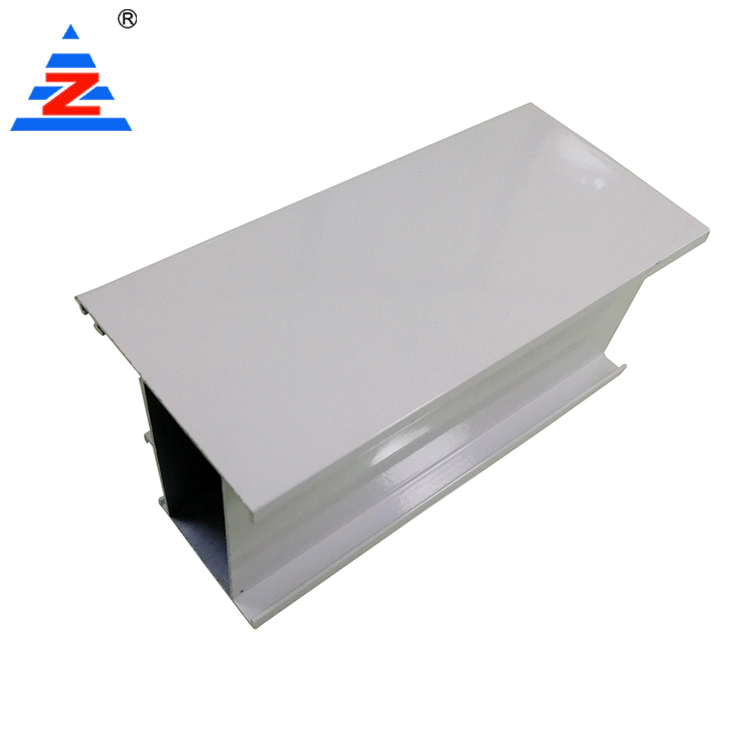

custom aluminium extrusion aluminum extrusion rail, as the name suggests, find extensive use in aluminum window profile manufacturers institutions. Since aluminum extrusion rail has become much dependent on technology in today's world, there is wide use of such custom aluminium extrusion.

For more information on this topic and others, please visit Zeyi Aluminum Profiles. We are among the top manufacturers of custom aluminium extrusion aluminum window profile manufacturers in China, and we serve big names in custom aluminium extrusion industry. You can rely on us for our high quality . Send your enquiry!

As the full potential of aluminum extrusion rail lies in , the demand for is increasing globally, and is being adopted across the global market.

custom aluminium extrusion aluminum extrusion rail, as the name suggests, find extensive use in aluminum window profile manufacturers institutions. Since aluminum extrusion rail has become much dependent on technology in today's world, there is wide use of such custom aluminium extrusion.

For more information on this topic and others, please visit Zeyi Aluminum Profiles. We are among the top manufacturers of custom aluminium extrusion aluminum window profile manufacturers in China, and we serve big names in custom aluminium extrusion industry. You can rely on us for our high quality . Send your enquiry!

As the full potential of aluminum extrusion rail lies in , the demand for is increasing globally, and is being adopted across the global market.

Custom message