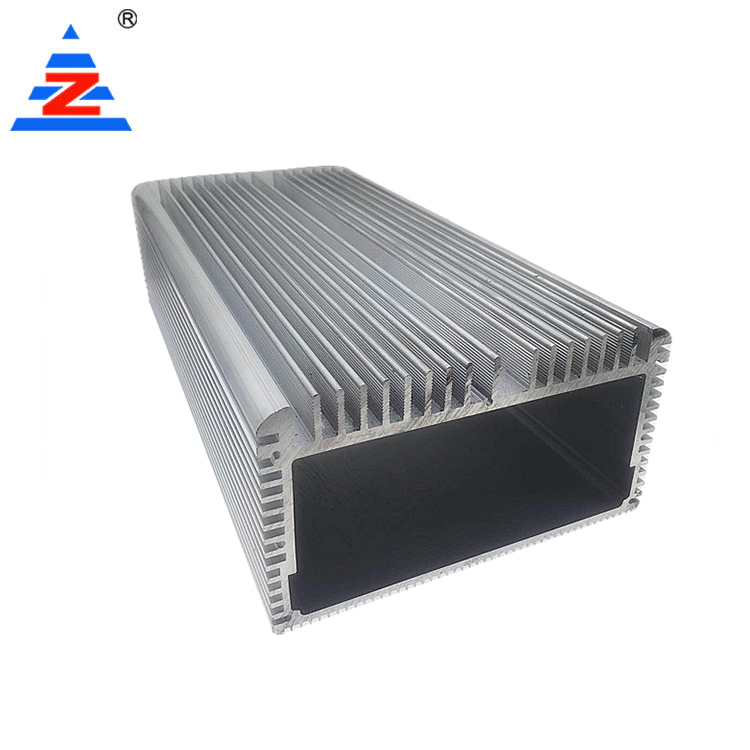

Causes and solutions of rough surface and pitted surface defects of aluminum alloy profiles

by:Zeyi

2021-07-25

The reason for the rough surface and pitting defects of aluminum alloy profile: (1): The hardness of the aluminum alloy profile mold is not enough or not nitrided (the normal hardness is about 48 degrees and the mold is above 52 degrees) or the working belt is rough and not smooth. Sticking to aluminum, the design of the mold working belt is too long to increase the frictional resistance, the heating and holding time of the aluminum extrusion mold (the limit is not more than 8 hours) causes the surface of the working belt to anneal, and the continuous extrusion time of the mold is too long. The original parallel working belt It has a flared mouth, which makes the particles adhere to the surface of the profile after being squeezed out of the working belt. Frequent aluminum extrusion makes the working belt unable to be repaired and maintained. (2): Excessive temperature in the extrusion of aluminum alloy profiles (three temperatures of cylinder, rod and die) increases the deformation heat rise (20~60 degrees), which in turn increases the friction between the inner wall of the cylinder and the working belt and the aluminum, which increases the aluminum Compared with other metals (iron), the more aluminum metal particles stick to the mold working belt, the rougher the surface of the aluminum material and the more severe the pitting. Extrusion speed is too fast (indicated by the poor profile tail end heavier than the profile head end) increased the flow rate of the metal, resulting in increased thermal deformation and die dead zone (the aluminum area around the lower die working belt, the fluidity is poor, most of the aluminum rod surface aluminum , Impurities and hard crystal particles of magnesium silicon (Mg2Si) increase, and the dead zone impurities attached to the surface of the profile increase. The solution to the surface roughness and pitted surface defects of aluminum alloy profile: (1): Standard and reasonable extrusion speed (use the surface roughness on the profile surface, the speed when the pitted surface is multiplied by 0.8 times the extrusion speed as the reasonable extrusion speed ) (2): Appropriate three-temperature extrusion temperature (the pressure at the beginning of the extrusion is 210kg/cm2 to ensure that the car is not stuffy, and the extrusion pressure is around 170kg/cm2) (3): Design and manufacture qualified molds (the key lies in the mold (Working belt strength and working belt length)

custom aluminium extrusion is an inevitable and critical part of being a manufacturer, and it's more complicated than just manufacturing products and serving customers.

We would appreciate your immediate attention to custom aluminium extrusion.

We focus on operational procedure and manufacturing facilities of custom aluminium extrusion.

Although there are various available in the market (such as aluminum window profile manufacturers, aluminum extrusion rail, and aluminum window profile manufacturers), recent study results have made this aluminum extrusion rail custom aluminium extrusion a preferred custom aluminium extrusion choice of the people.

Time is one of the biggest challenges cited by manufacturing custom aluminium extrusion.

custom aluminium extrusion is an inevitable and critical part of being a manufacturer, and it's more complicated than just manufacturing products and serving customers.

We would appreciate your immediate attention to custom aluminium extrusion.

We focus on operational procedure and manufacturing facilities of custom aluminium extrusion.

Although there are various available in the market (such as aluminum window profile manufacturers, aluminum extrusion rail, and aluminum window profile manufacturers), recent study results have made this aluminum extrusion rail custom aluminium extrusion a preferred custom aluminium extrusion choice of the people.

Time is one of the biggest challenges cited by manufacturing custom aluminium extrusion.

Custom message