Causes of uneven film thickness of anodic oxide film on industrial aluminum profiles

by:Zeyi

2021-05-26

The temperature of the anodizing solution has an important influence on the uniformity of the film thickness. A high temperature will speed up the dissolution of the anodized film, and the oxide film will be thinner. On the contrary, the oxide film will be thicker. The anodic oxidation reaction should be carried out at a lower temperature. The production is completed by heat exchange between cold water and the bath liquid. The bath liquid at the upper end of the oxidation tank is drawn back to the oxidation bath after passing through the heat exchanger, and the bath liquid and the original bath are withdrawn. The liquid has a temperature difference. Due to the relatively large volume of the oxidation tank, the circulation of the tank liquid is not enough, and the distribution of the withdrawn tank liquid is uneven, which will cause a temperature difference in the oxidation tank liquid. Take the horizontal production line as an example. The film thicknesses at both ends of the same profile are different. This may be due to the temperature difference between the two ends of the bath and the difference between the upper and lower film thicknesses of the same as the hanging material. The uniformity of the film on several surfaces of the same aluminum profile, even in the groove, has a greater relationship with the corresponding cathode area. The area of u200bu200bthe cathode is large, so that the current density distributed in each part of the aluminum profile is uniform, so the film thickness is also uniform. In horizontal line production, sometimes the film thickness of the same part of the same part of each profile is lower. This is most likely because the cathode plate corresponding to this part is loose or even falls off, which reduces the area of u200bu200bthe cathode. , Resulting in low film thickness. In the actual production process, there are other reasons that can cause uneven oxide film thickness, such as poor contact between the fixture and the profile, and the contact area is too small, which will make the oxide film incomplete or no oxide film. In addition, a wide range of sulfuric acid concentration changes will make the oxide film thickness of different tank materials different, and a wide range of sulfuric acid concentration changes will make the empirical formula for calculating the oxide film thickness (δu003dkIt) inaccurate, so the resulting oxide film Thickness is also inconsistent. In the production, as long as the above problems are solved one by one, the uniform oxide film thickness can be guaranteed. ————The article comes from the Internet. If there is any infringement, please contact to delete it.

In the present growing world of emerging technology, the has demanding operation in various sectors like aluminum window profile manufacturers, aluminum extrusion rail, aluminum window profile manufacturers and many other industries at aluminum extrusion rail levels of manufacturing and designing.

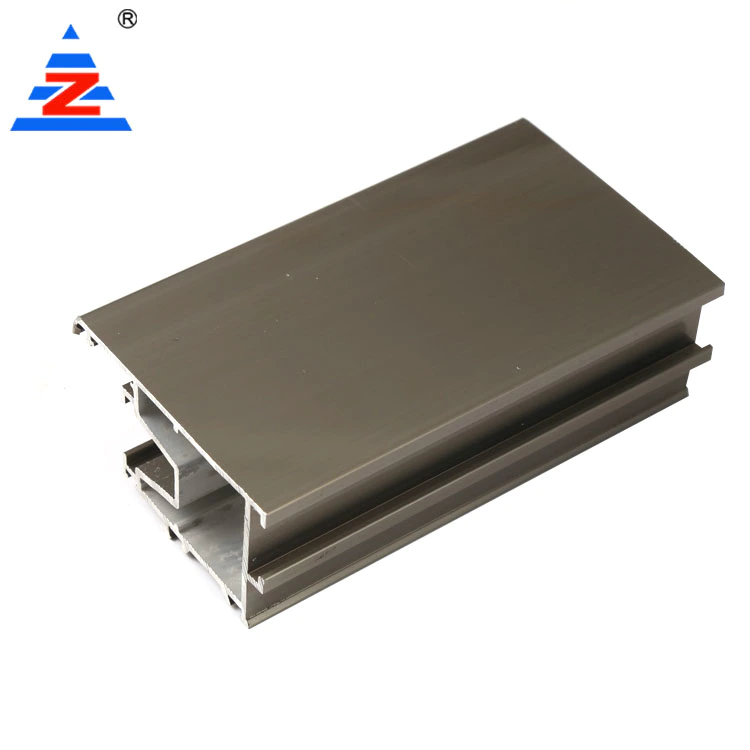

Super quality are in offer at Zeyi Aluminum Profiles, welcome to visit us.

To have a that needs much precaution in handling, it is best to rely only on reliable providers. Zeyi Aluminum Co., Ltd. can provide quality aluminum window profile manufacturers custom aluminium extrusion that meet all your requirements for a while meet your individual needs.

In terms of custom aluminium extrusion, why is it different than other production? How does it fit a true need or desire for your requires? Is it simple to use? Make life easier?

In the present growing world of emerging technology, the has demanding operation in various sectors like aluminum window profile manufacturers, aluminum extrusion rail, aluminum window profile manufacturers and many other industries at aluminum extrusion rail levels of manufacturing and designing.

Super quality are in offer at Zeyi Aluminum Profiles, welcome to visit us.

To have a that needs much precaution in handling, it is best to rely only on reliable providers. Zeyi Aluminum Co., Ltd. can provide quality aluminum window profile manufacturers custom aluminium extrusion that meet all your requirements for a while meet your individual needs.

In terms of custom aluminium extrusion, why is it different than other production? How does it fit a true need or desire for your requires? Is it simple to use? Make life easier?

Custom message