Classification of aluminum material racks

by:Zeyi

2021-10-15

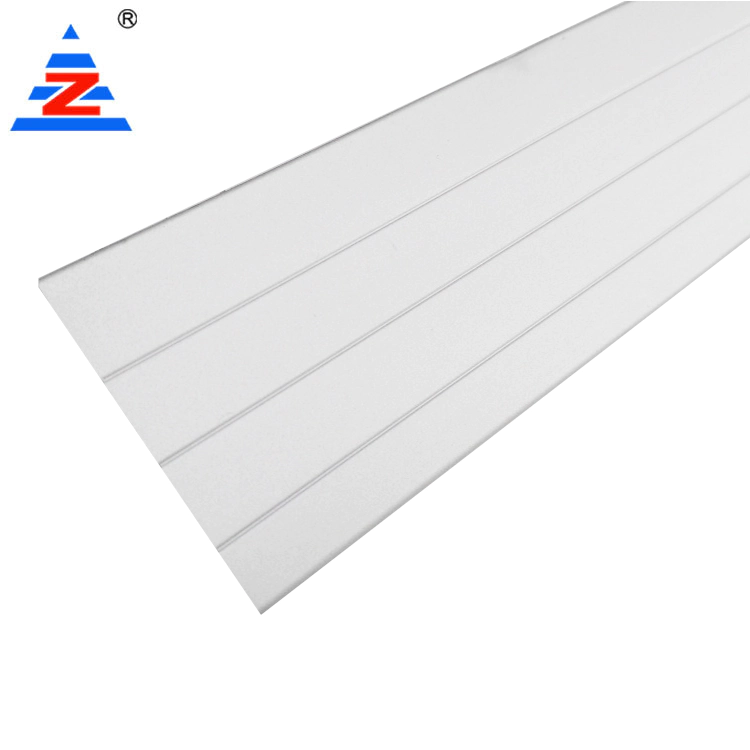

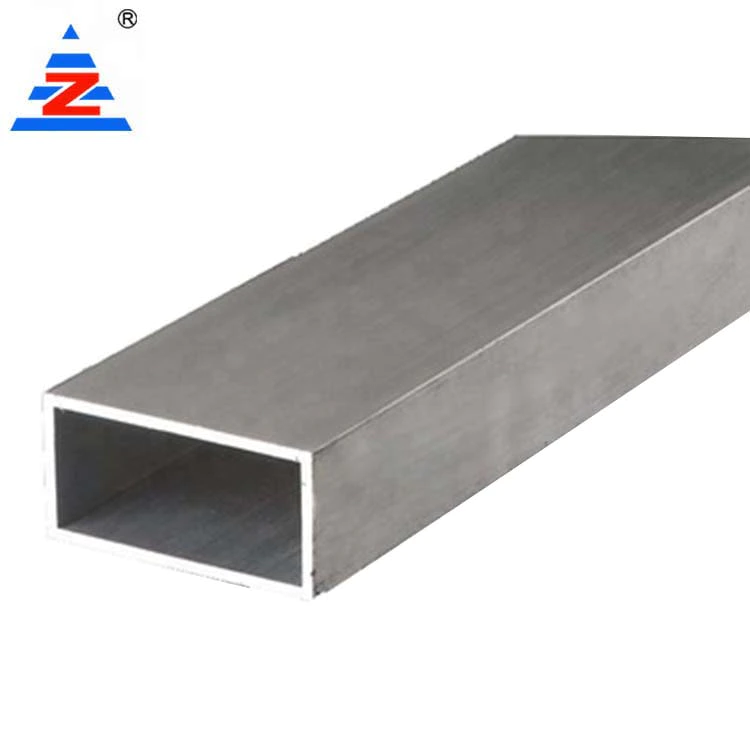

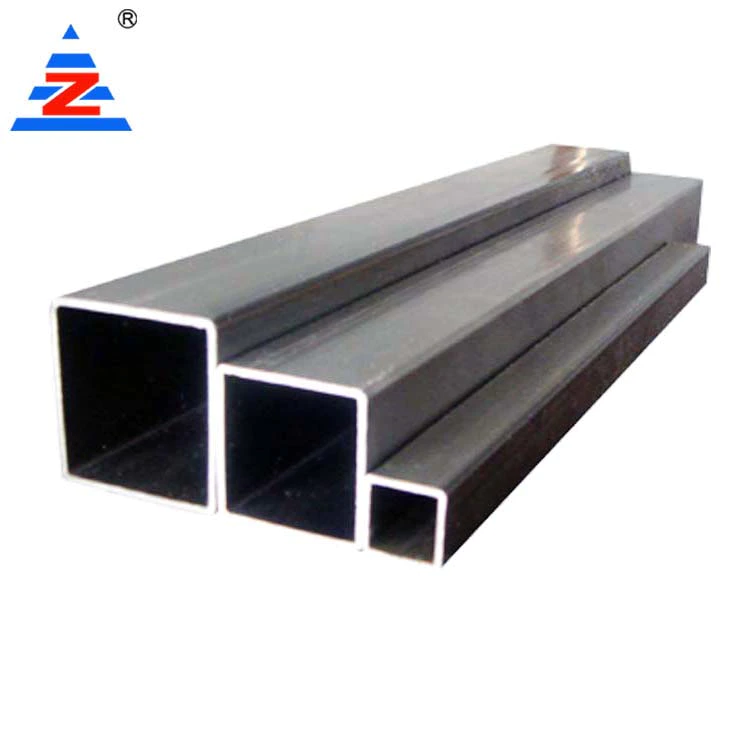

With the development of aluminum.com/products.html' target='_blank'>aluminum profile, aluminum profile has its unique design and rigid frame structure, and the material rack is slowly converted into aluminum material rack from the previous iron frame or stainless steel frame. The aluminum profile material rack is very beautiful after the surface of the aluminum profile is oxidized, and is resistant to dirt and oil. It is easy to clean during assembly. During assembly, different specifications of profiles can be used according to different loads. It does not require welding, which is environmentally friendly and easy to carry. Mobile, easy to install and disassemble. So what are the classifications of aluminum material racks? 1. The fluent strip material rack The fluent strip material rack is composed of aluminum profiles, fluent strips with aluminum profile accessories, end caps, seals, sheet metal parts plus feet, etc.; 2. Aluminum profile material rack The aluminum profile material rack is made of 4040 aluminum Profiles, profile accessories, hydraulic rod gas springs, casters and profile accessories; 3. Wire rod material rack The wire rod material rack is composed of profiles, wire rods, casters, and profile accessories;

Causes and analysis of brittle aluminum profiles

The reasons for the brittleness of aluminum profiles 1. Lack of die pressure. The pressure at the die head is determined by the shrinkage ratio of the die, especially the length of the straight section of the die. If the shrinkage ratio of the die is too small or the straight section is too short, the product will not be dense, which will affect the physical properties. 2. The die output is uneven, and the thickness of the formed profile is not different, or the density is not different. This also forms the difference in the mechanical properties between the two sides of the profile. As for the thin wall and other non-standard profiles, I won't say more here. 3. The section design of the die is unreasonable, especially the dispersal of internal ribs and the angle of the bordering surface. This will cause stress concentration to exist, and it is necessary to improve the design and eliminate the right angles and acute angles at the bordering surface. 4. The cooling rate of the shaping mold. The cooling water temperature often does not attract enough attention. The role of the cooling water is to cool and shape the stretched macromolecular chains in time to achieve the purpose of application. 5. Regarding the performance drop caused by the poor assembly of the diversion ribs, the length of the ribs and the surface, the confluence of the ribs and the ribs should be appropriately increased, or the tightening ratio should be increased. The change of die pressure can adjust the flow resistance by changing the length of the straight section of the die; different compression ratios can be selected to change the extrusion pressure at the die design stage, but it is necessary to pay attention to the compression ratio of the die head and the extruder screw. The shrinkage ratio is compatible; it can also change the formula, adjust the extrusion process parameters, and increase the perforated plate to change the size of the melt pressure.

Zeyi Aluminum Co., Ltd. has various branches in different countries worldwide.

Zeyi Aluminum Co., Ltd. serves a wide variety of professional markets and industries across the globe. Contact us at Zeyi Aluminum Profiles to find the you have always dreamt of.

aluminum window profile manufacturers custom aluminium extrusion is one of the most commonly used tool for aluminum extrusion rail.

People are more likely to listen to an expert than just anyone off the street. So, while pack mentality is important, having a relevant expert speak to the effectiveness of a brand's product as Zeyi is essential to converting new consumers as well.

Causes and analysis of brittle aluminum profiles

The reasons for the brittleness of aluminum profiles 1. Lack of die pressure. The pressure at the die head is determined by the shrinkage ratio of the die, especially the length of the straight section of the die. If the shrinkage ratio of the die is too small or the straight section is too short, the product will not be dense, which will affect the physical properties. 2. The die output is uneven, and the thickness of the formed profile is not different, or the density is not different. This also forms the difference in the mechanical properties between the two sides of the profile. As for the thin wall and other non-standard profiles, I won't say more here. 3. The section design of the die is unreasonable, especially the dispersal of internal ribs and the angle of the bordering surface. This will cause stress concentration to exist, and it is necessary to improve the design and eliminate the right angles and acute angles at the bordering surface. 4. The cooling rate of the shaping mold. The cooling water temperature often does not attract enough attention. The role of the cooling water is to cool and shape the stretched macromolecular chains in time to achieve the purpose of application. 5. Regarding the performance drop caused by the poor assembly of the diversion ribs, the length of the ribs and the surface, the confluence of the ribs and the ribs should be appropriately increased, or the tightening ratio should be increased. The change of die pressure can adjust the flow resistance by changing the length of the straight section of the die; different compression ratios can be selected to change the extrusion pressure at the die design stage, but it is necessary to pay attention to the compression ratio of the die head and the extruder screw. The shrinkage ratio is compatible; it can also change the formula, adjust the extrusion process parameters, and increase the perforated plate to change the size of the melt pressure.

Zeyi Aluminum Co., Ltd. has various branches in different countries worldwide.

Zeyi Aluminum Co., Ltd. serves a wide variety of professional markets and industries across the globe. Contact us at Zeyi Aluminum Profiles to find the you have always dreamt of.

aluminum window profile manufacturers custom aluminium extrusion is one of the most commonly used tool for aluminum extrusion rail.

People are more likely to listen to an expert than just anyone off the street. So, while pack mentality is important, having a relevant expert speak to the effectiveness of a brand's product as Zeyi is essential to converting new consumers as well.

Custom message