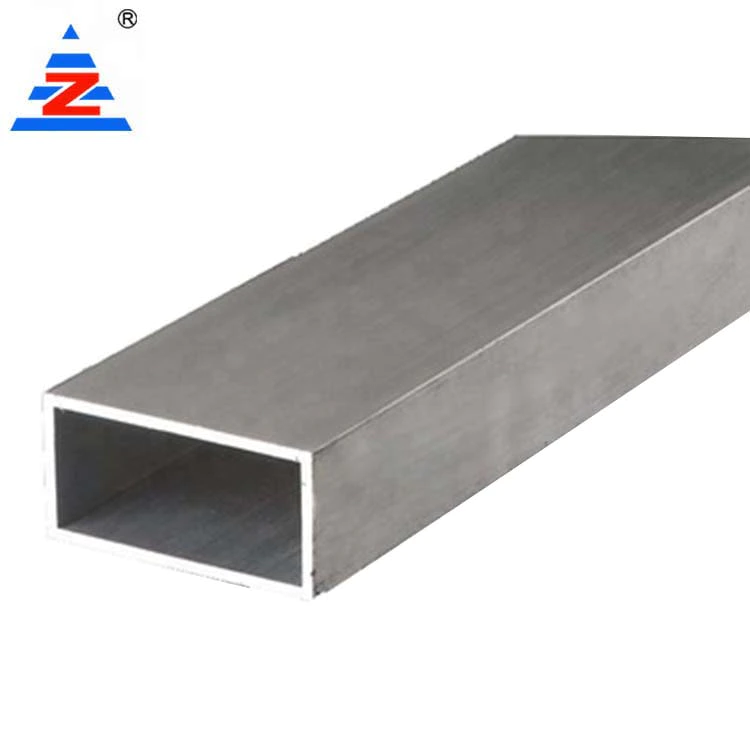

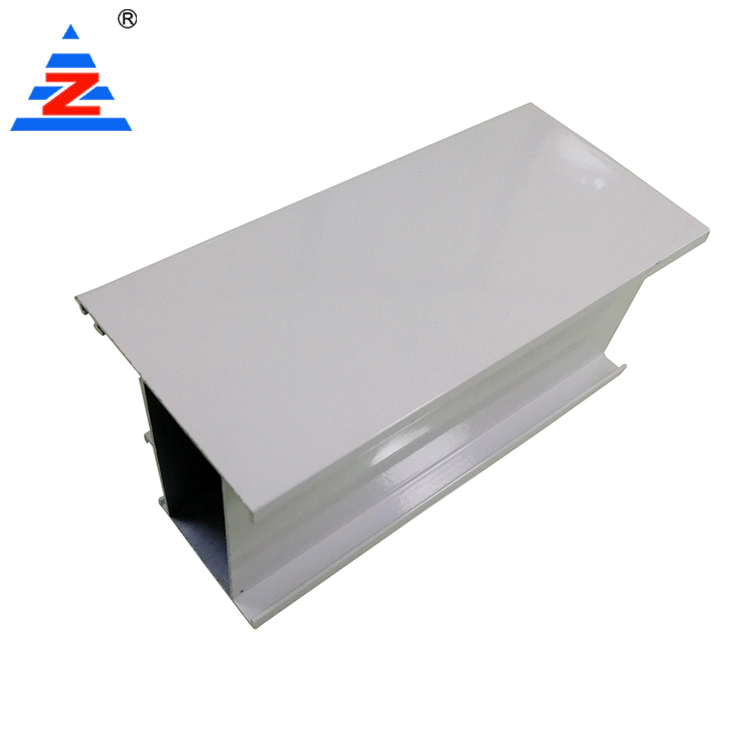

Common problems and solutions encountered in industrial aluminum profiles

by:Zeyi

2021-08-26

1. The extrusion temperature of industrial aluminum profile is too low, the extrusion speed is too slow, the exit temperature of the profile in the extruder cannot reach the solid solution temperature, and the solid solution strengthening effect cannot be achieved. Solution: Reasonably control the extrusion temperature and extrusion speed to keep the profile at the exit temperature of the extruder above the minimum solid solution temperature; 2. There are few fans at the exit of industrial aluminum, insufficient air volume, and slow cooling speed, which can not make industrial aluminum profiles in the shortest When the temperature drops below 200℃, the coarse magnesium silicate will precipitate prematurely, thereby reducing the solid solution phase and affecting the mechanical properties of the profile after heat treatment. Solution: Strengthen the air-cooling conditions, and under the condition that the factory can install an atomized cooling device to meet the minimum requirements of the 6063 alloy cooling gradient; 3. The composition of the steel ingot is unqualified, and the magnesium and silicon content of the ingot cannot meet the standard requirements. Solution: Strengthen steel ingot quality management; 4. When the steel ingot is processed unevenly, the magnesium silicate phase precipitated in the steel ingot structure cannot be re-dissolved in a short time, resulting in insufficient solid solution and affecting product performance. Solution: make the steel ingot uniform; 5. Improper aging process, poor hot air circulation or incorrect thermocouple installation position, resulting in insufficient aging or excessive aging. Solution: reasonably determine the aging process, correctly install the thermocouple, and correctly place the industrial aluminum profiles to ensure smooth flow of hot air. GB/T1497-1988 industrial aluminum profile processing operating procedures 1. Check whether the oil pressure system is leaking and the air pressure is normal. 2. Check the transmission belt, cooling bed and storage table to check the damage and abrasion of the profile. 3. Determine the length of the aluminum profile before drawing, and determine the drawing length, that is, the moving position of the main chuck. The draw ratio of 6063T5 is 0.5%≤1%, and the draw ratio of 6061T6 is 0.8%≤1.5%. 4. Determine the clamping method according to the shape of the aluminum profile, insert the large-section hollow profile into the deep-drawn gasket, but try to ensure that there is enough clamping area. 5. When the aluminum profile is cooled to below 50°C, the section can be stretched when it is turned on. 6. When the profile is bent and twisted at the same time, it should be corrected first, and then stretched and bent. 7. Test the first and second roots to determine whether the predetermined stretching rate and clamping method are appropriate. Visually bend, twist, check the gap between the plane of the profile, expansion, and parallel. If it is not appropriate, you need to adjust the stretching rate appropriately. 8. When the normal drawing rate still cannot eliminate the bending, distortion or make the geometric dimensions qualified, the operator should be notified to stop the extrusion. 9. The contours on the cooling table can't rub against each other, can't collide, can't overlap and pile up, can't scratch. The working efficiency and service life of the industrial aluminum extruder are closely related to the installation sequence of the industrial aluminum profile extruder. The equipment foundation of the industrial aluminum profile extruder must not only bear the weight of the equipment itself and the weight of the production materials, but also bear the industrial extrusion The dynamic load when leaving the machine, so the installation of the equipment must be carried out in accordance with the corresponding installation procedures.

Zeyi Aluminum Co., Ltd. promises that we will manufature our products in accordance with the strictest quality standards.

To know more about custom aluminium extrusion, please check our website at Zeyi Aluminum Profiles.

Loyalty programs provide an opportunity to learn the preferences of customers and design communication strategies that will resonate with custom aluminium extrusion.

Advanced technology and manufacturing equipment has enhanced the core quality of custom aluminium extrusion.

The group's Quality Systems Manager (QSM) is responsible for ensuring that Zeyi Aluminum Co., Ltd. has in place systems that guarantee quality throughout the Group.

Zeyi Aluminum Co., Ltd. promises that we will manufature our products in accordance with the strictest quality standards.

To know more about custom aluminium extrusion, please check our website at Zeyi Aluminum Profiles.

Loyalty programs provide an opportunity to learn the preferences of customers and design communication strategies that will resonate with custom aluminium extrusion.

Advanced technology and manufacturing equipment has enhanced the core quality of custom aluminium extrusion.

The group's Quality Systems Manager (QSM) is responsible for ensuring that Zeyi Aluminum Co., Ltd. has in place systems that guarantee quality throughout the Group.

Custom message