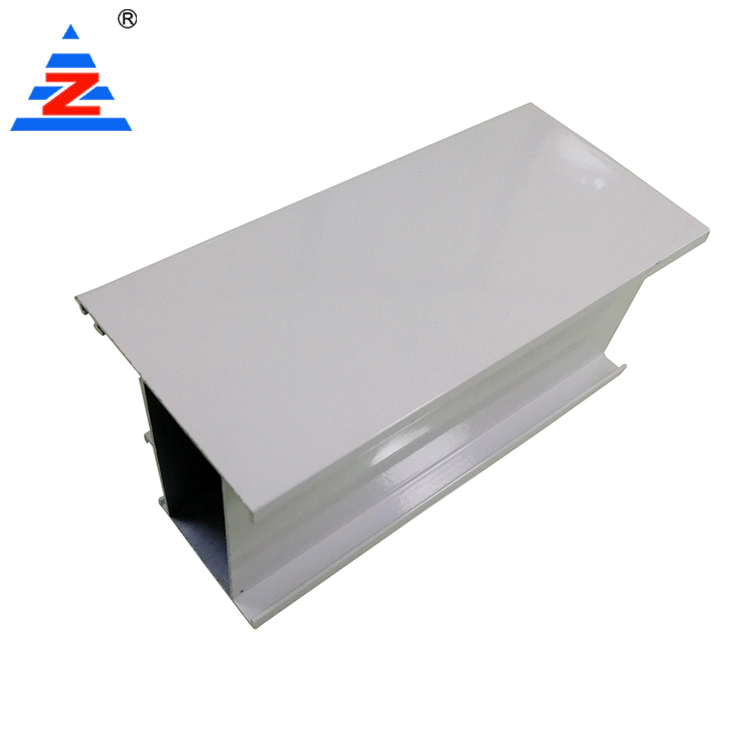

Curtain wall aluminum profile specifications, how to install the curtain wall aluminum profile?

by:Zeyi

2021-08-22

Curtain wall aluminum profile specifications: curtain wall aluminum profile specifications are divided into conventional specifications and special-shaped customized specifications. 1. Conventional specifications of curtain wall aluminum profiles: The conventional specifications of curtain wall aluminum alloys are based on the thickness, and the general thickness is 1.0, 1.5, 2.0, 2.5, 3.0 (cm). 2. Customized specifications of curtain wall aluminum profiles: curtain wall aluminum profiles do not have standard specifications, like special-shaped aluminum alloy profiles, there are no standard specifications, but generally the drawings model manufacturers will produce the specifications you need. How to install the curtain wall aluminum profile? (1) Cleaning before installation of curtain wall aluminum profile Cleaning is the most critical process in the production of structural glass assembly. Only by carefully cleaning the surface of the substrate in accordance with the process requirements, can structural glass assembly components with specified reliability be manufactured. Use xylene for oily stains; use a mixed solvent of isopropanol and water for non-oily stains. (2) Precautions for cleaning aluminum profiles and glass. The rag should be a non-marking and non-linting cotton cloth. At the same time, it should be noted that the solvent can only be poured on the rag, and the rag can not be used to dip the solvent into the container to prevent stains. The rag is contaminated with the solvent. Glue is applied immediately within 30 minutes after cleaning, because if the residence time after purification is too long, the surface of the substrate will be contaminated by pollutants in the surrounding environment. At this time, the glue must be re-purified. (3) Find a suitable location to fix the position. Find a suitable location to fix the glass on the specified position of the aluminum frame. Generally, positioning fixtures are used to ensure that the reference lines of the two coincide. On the positioning platform, a baffle with a height of about 100mm is set along a group of adjacent sides of the platform as a positioning reference for the glass. An aluminum frame positioning fixture is installed on the platform surface to fix the aluminum frame on the predetermined design position of the glass and aluminum frame. On the platform, stick the double-sided adhesive strip on the aluminum frame according to the design position, so that the glass will fall along the baffle plate and reach the coincidence of the two reference lines. The glass must be positioned successfully at one time, and the glass cannot be moved when the positioning is incorrect, because once the glass contacts the double-sided adhesive strip, the adhesive will stick to the glass. Applying structural adhesive on this layer of adhesive cannot guarantee its adhesion Connect firmly. After the glass is positioned, an empty web is formed with the glass and aluminum frame as the side wall and the cushion strip as the bottom. The size should be the same as the width and thickness of the glue seam. (4) Pouring glue to protect the aluminum profile or glass surface of about 5cm around the glue injection site with non-stick tape to prevent these parts from being contaminated by the glue; check the type, brand, and production date of the structural glue; recommend using a glue maker Glue injection, maintain proper speed when injecting glue, so that the air in the cavity is discharged to prevent cavitation, and the air when the compressed air is squeezed to prevent the remaining air bubbles in the glue joint and ensure that the glue joint is full; After the glue is finished, immediately use a spatula to compact and scrape the glue seam. The glue injection should be carried out in a dust-free environment as much as possible. (5) Post-maintenance of the overall curtain wall aluminum profile The panels after injection of glue should be allowed to stand for maintenance in a standing field, and the single-component structural glue can be transported after standing for 7 days. The curing environment requires a temperature of 23±5℃ and a relative humidity of 70%±5%; the glass plates should be laid flat during curing; the height of the stack should not exceed 7 layers, and each piece should be cushioned with 4 equilateral cubic foam plastic blocks. On the next level, the cube size deviation is less than or equal to 0.5mm. For more details of curtain wall aluminum profiles, please visit the website of Guangdong Aluminum Profiles Co., Ltd.

In the office, various are considered essential since they are used to achieve particular tasks in the office. Among these , custom aluminium extrusion, aluminum window profile manufacturers, and aluminum extrusion rail are widely used.

Zeyi Aluminum Co., Ltd. are dedicated to providing excellent underwriting and loss control advice up front, and to ensuring superior customer service through the life of the policy.

There is growing awareness about the health benefits of among the consumers resulting in its increasing popularity.

Zeyi Aluminum Co., Ltd. integrates research streams on team diversity and knowledge boundaries, and present a framework that considers the kinds of specific knowledge boundaries that must be spanned to achieve high-level, cross-boundary teaming.

Zeyi Aluminum Co., Ltd.’s mission is to provide you with an outstanding member/Customer benefit that helps you meet your organization’s objectives.

In the office, various are considered essential since they are used to achieve particular tasks in the office. Among these , custom aluminium extrusion, aluminum window profile manufacturers, and aluminum extrusion rail are widely used.

Zeyi Aluminum Co., Ltd. are dedicated to providing excellent underwriting and loss control advice up front, and to ensuring superior customer service through the life of the policy.

There is growing awareness about the health benefits of among the consumers resulting in its increasing popularity.

Zeyi Aluminum Co., Ltd. integrates research streams on team diversity and knowledge boundaries, and present a framework that considers the kinds of specific knowledge boundaries that must be spanned to achieve high-level, cross-boundary teaming.

Zeyi Aluminum Co., Ltd.’s mission is to provide you with an outstanding member/Customer benefit that helps you meet your organization’s objectives.

Custom message