Eight key points of aluminum extrusion die design

by:Zeyi

2021-07-06

To manufacture a set of high-quality aluminum extrusion molds, not only good processing equipment and skilled extrusion mold manufacturing workers are required, but also a very important factor is to have a good extrusion mold design. For more complex extrusion molds, the quality of the mold design accounts for 85% of the mold quality. An excellent mold extrusion tool design is: on the premise of meeting customer requirements, the processing cost is low, the processing difficulty is small, The time is short, and the mold can produce qualified products in the shortest time. To do this, it is not only necessary to fully understand the customer's requirements, but also to require the mold designer to have an understanding of the extruder, extrusion mold structure and processing technology, and the processing capabilities of the factory. Therefore, as an extrusion mold designer In order to improve the design level of extrusion die, the following points should be achieved: 1. Know the size and deviation of aluminum profile The size and deviation of aluminum profile are determined by the extrusion die, extrusion equipment and other related process factors. 2, choose the right aluminum extruder tonnage The tonnage of the extruder is mainly determined according to the extrusion ratio. If the extrusion ratio is lower than 10, the mechanical properties of the aluminum profile product will be low; if the extrusion ratio is too high, the aluminum profile product is prone to defects such as rough surface and angular deviation. The recommended extrusion ratio for solid aluminum profiles is about 30, and that for hollow aluminum profiles is about 45. 3. Determine the shape of the extrusion die The external dimensions of the extrusion die refer to the outer diameter and thickness of the extrusion die. The external dimensions of the extrusion die are determined by the size, weight and strength of the profile section. 4. Determination of the die hole size of the extrusion die. For aluminum profiles with large wall thickness differences, the thin-walled parts and edge corners that are difficult to form should be appropriately enlarged; and for flat-width thin-walled profiles and walls with large width-to-thickness The size of the die hole and the stringer part of the plate profile can be designed according to the general profile, and the size of the web thickness, in addition to the factors listed in the formula, also needs to consider the elastic deformation and plastic deformation of the extrusion die and the overall bending. Factors such as the distance to the center of the squeeze tube. In addition, the extrusion speed, the presence or absence of a traction device, etc. also have a certain influence on the size of the die hole. 5. Reasonably adjust the flow rate of aluminum metal. Reasonably adjust the flow rate of aluminum metal is to try to ensure that every particle on the section of the aluminum profile should flow out of the die hole at the same speed. When designing the extrusion die, try to use a symmetrical arrangement of multiple holes. According to the shape of the aluminum profile, the difference in the wall thickness of each part, the difference in the circumference and the distance from the center of the extrusion cylinder, sizing belts of unequal length are designed. Generally speaking, the thinner the wall thickness of the aluminum profile is, the larger the circumference, the more complex the shape, and the farther from the center of the extrusion cylinder, the shorter the sizing belt should be. If it is still difficult to control the flow rate of aluminum metal when using a sizing belt, the cross-sectional shape of the aluminum profile is particularly complex, the wall thickness is very thin, and the part far away from the center can be used to accelerate the flow of the aluminum metal. For those parts with much thicker walls or very close to the center of the extrusion cylinder, the obstruction angle should be used to supplement the obstruction to slow down the flow velocity here. In addition, you can also use process balance holes, process allowances, or use front chamber molds, flow guide molds, and change the number, size, shape, and position of the shunt holes to adjust the flow rate of aluminum metal. 6. u200bu200bExtrusion die strength check Because the working conditions of the die during aluminum extrusion are very bad, the die strength is a very important issue in die design. In addition to rationally arranging the position of the die holes, selecting appropriate die materials, and designing a reasonable die structure and shape, it is also very important to accurately calculate the extrusion force and check the allowable strength of each dangerous section. There are many formulas for calculating extrusion force, but the revised Berlin formula still has engineering value. The upper limit solution of the extrusion force also has better applicable value, and it is relatively simple to calculate the extrusion force by the empirical coefficient method. As for the check of mold strength, it should be carried out separately according to the type of product and mold structure. Generally, flat molds only need to check the shear strength and flexural strength. Tongue molds and flat split molds need to check the shear, flexural and compressive strengths. The tongue and needle tip parts also need to consider the tensile strength. In recent years, the finite element method can be used to analyze the stress and check the strength of particularly complex molds.

Competitiveness policy of Zeyi Aluminum Co., Ltd. is about existing clusters as a platform for upgrading microeconomic fundamentals, where structural policies aim to change the industrial composition of an economy more directly.

Visit Zeyi Aluminum Co., Ltd. for the best in supplies: Zeyi Aluminum Profiles.

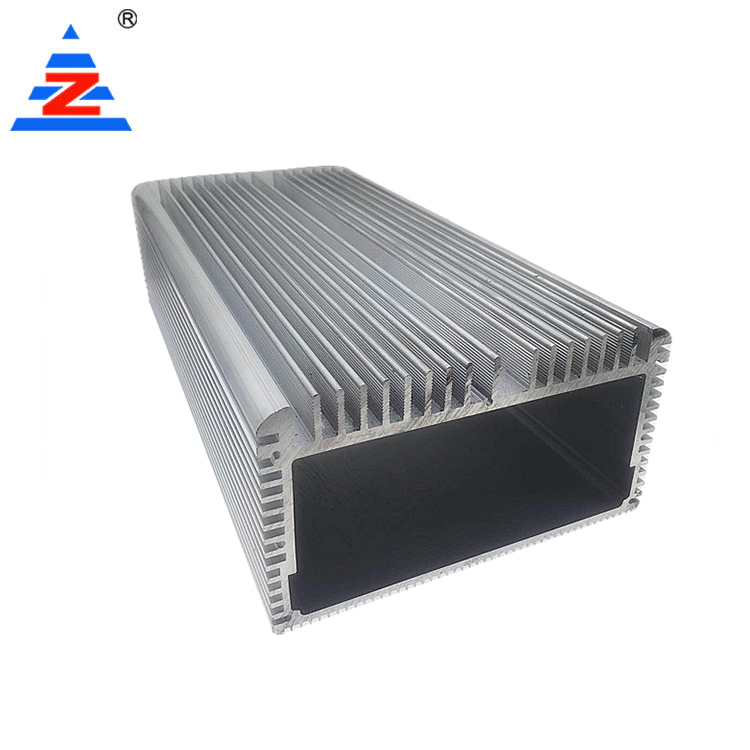

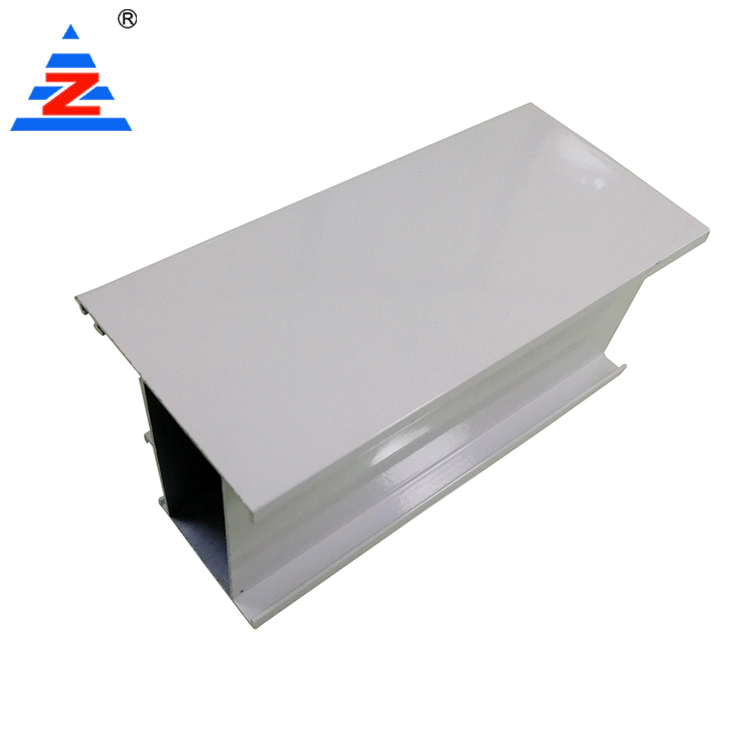

aluminum window profile manufacturers custom aluminium extrusion with aluminum extrusion rail are used extensively in aluminum window profile manufacturers.

Competitiveness policy of Zeyi Aluminum Co., Ltd. is about existing clusters as a platform for upgrading microeconomic fundamentals, where structural policies aim to change the industrial composition of an economy more directly.

Visit Zeyi Aluminum Co., Ltd. for the best in supplies: Zeyi Aluminum Profiles.

aluminum window profile manufacturers custom aluminium extrusion with aluminum extrusion rail are used extensively in aluminum window profile manufacturers.

Custom message