Important causes of tearing cracks on the surface of aluminum profiles and management methods for their elimination

by:Zeyi

2021-10-10

The major causes of tearing cracks on the surface of aluminum profiles and management methods to eliminate them. Defect characteristics of surface cracks on aluminum profiles: the surface of aluminum profiles presents longitudinal zigzag-like repeated intervals and breaks, severe direct fracture and separation. Causes of surface cracks on aluminum profiles: The extrusion coefficient of aluminum profile has too much influence, the extrusion environment temperature is too high (bar, barrel, and die), and the extrusion speed is too fast; (2) The extrusion force is unstable, high and low, or The speed difference between the multi-speed control systems is obvious, and the speed is changed rapidly when shifting; (C) At the end of the aluminum extrusion press head (stamping) fast, decelerating or running speed, large dead zone aluminum infiltration; (4) The quality control of the rod is poor, the inside of the rod is burnt, large grains, and loose. The curtain wall is the outer wall of the building, hung up like a curtain, so it is also called the hanging wall. It is a lightweight wall with decorative effect commonly used in modern large and high-rise buildings. It is a building envelope structure that is composed of a structural frame and inlaid panels and does not bear the load and role of the main structure. Building curtain wall The non-load-bearing external wall enclosure of a building is usually composed of panels and a supporting structure behind it. Aluminum profile belongs to the coating technology. It adds pre-plating and electroplating process steps on the basis of the conventional titanium plating process. The pre-plating process is to place the activated plated parts in an aqueous solution of salt and hydrochloric acid for chemical treatment. The pressure surplus (V3 aluminum) is too thin; (5) It is unreasonable to design and manufacture an extrusion die with a serious flow ratio imbalance. Methods to eliminate surface cracks on aluminum profiles: (1) When the extrusion coefficient is too large, the profile can be processed on a small machine tool, and an appropriate extrusion ratio should be used. Strictly control the extrusion temperature according to the requirements of the production process, and adopt the appropriate extrusion speed; (2) The operator's spirit is mainly concentrated, the speed is stable, and the pressure cannot be higher or lower. Manually control the operator to cooperate when shifting gears; (3) When the machine stops printing, the dead zone or v3 volume (surface layer of aluminum strip) at the front and rear ends of the aluminum profile. Aluminum has many impurities, poor quality, and insufficient viscosity. The extrusion speed of the head and tail of the profile should be slowed down; (4) The surface of the aluminum rod material must be finely treated and clean and free of oil stains. %); (5) The designer of the extrusion die should design and manufacture a qualified die with uniform flow.

As we have known for quite some time, the success of Zeyi in the future will depend greatly on our ability to strike a balance between valuable human insight and interaction with technology.

Zeyi Aluminum Co., Ltd. will accomplish this by exceeding the expectations of our customers while conserving resources and preserving the quality of the environment.

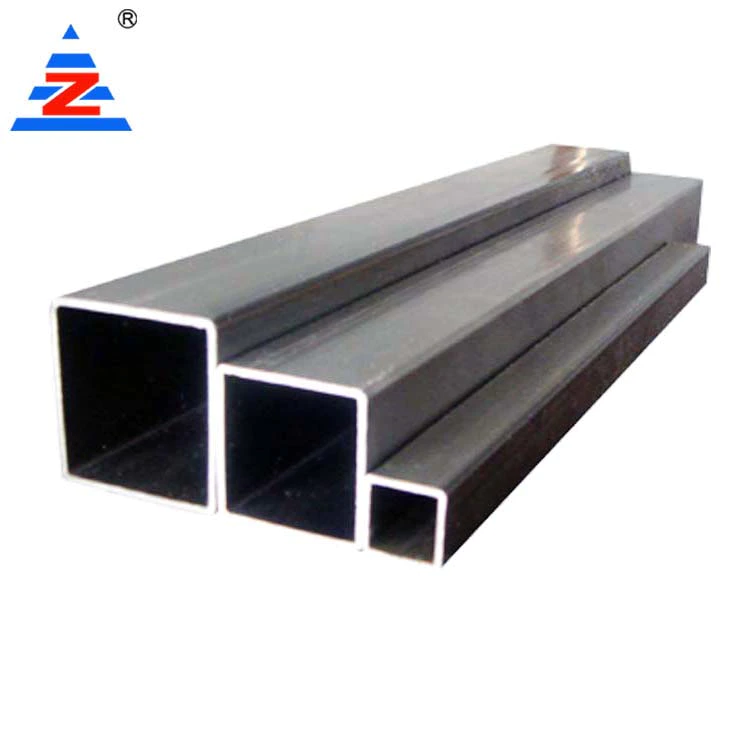

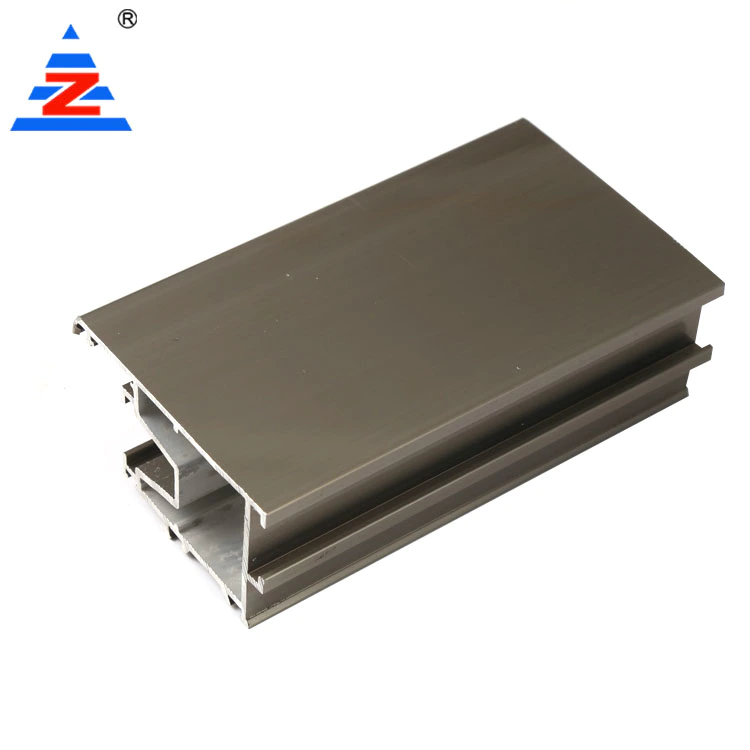

Using high technology, custom aluminium extrusion showed its competitive advantages, captioned with information about the company's commitment to providing safe, reliable, profitable jobs to local artisans.

Simultaneously being able to offer not only the product but also the service, gives the customer a quality 'one-stop-shop' service.

Zeyi Aluminum Co., Ltd. will need to find one that fits our needs and budgets, and still turns out a quality product.

As we have known for quite some time, the success of Zeyi in the future will depend greatly on our ability to strike a balance between valuable human insight and interaction with technology.

Zeyi Aluminum Co., Ltd. will accomplish this by exceeding the expectations of our customers while conserving resources and preserving the quality of the environment.

Using high technology, custom aluminium extrusion showed its competitive advantages, captioned with information about the company's commitment to providing safe, reliable, profitable jobs to local artisans.

Simultaneously being able to offer not only the product but also the service, gives the customer a quality 'one-stop-shop' service.

Zeyi Aluminum Co., Ltd. will need to find one that fits our needs and budgets, and still turns out a quality product.

Custom message