Industrial aluminum extrusion production process introduction

by:Zeyi

2021-08-04

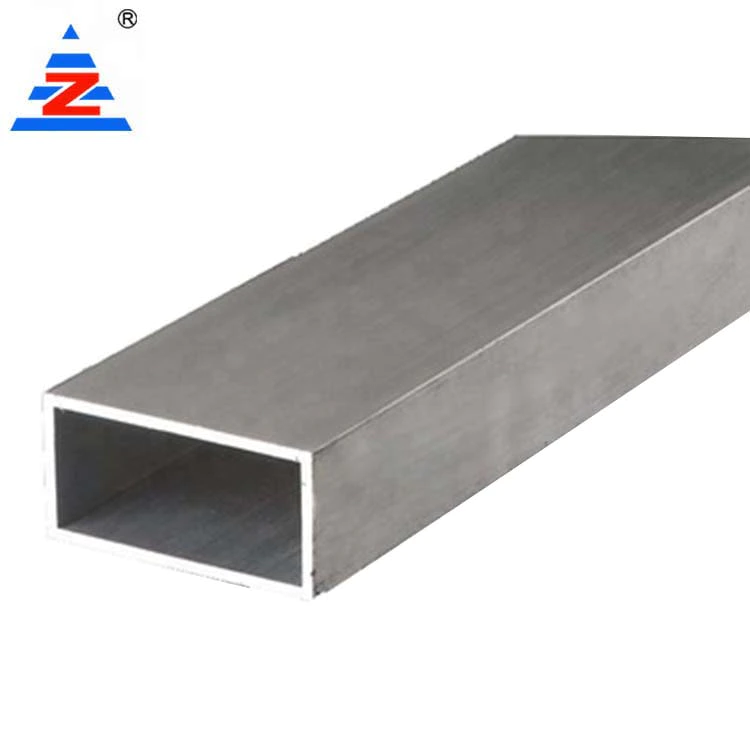

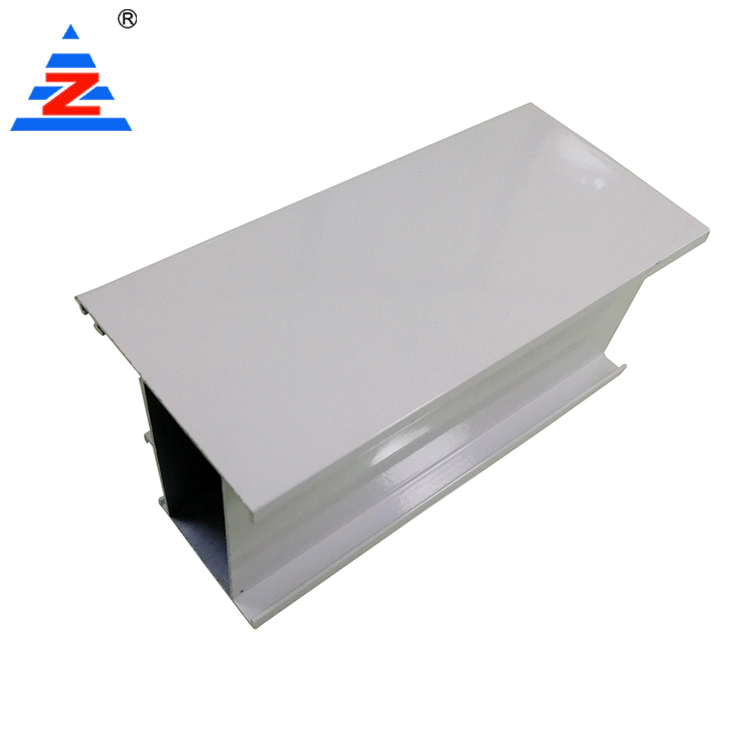

Whether in industry or life, aluminum profiles have been widely used. Extrusion of industrial aluminum profile profiles has also been of great concern to everyone. Compared with all kinds of industrial aluminum profiles that can be seen everywhere in daily life, industrial aluminum extrusion processing is not so easy to see. Let's explain the process of industrial aluminum extrusion production for everyone. 1: The selection of raw materials: profile is an industrial frame profile obtained by heating aluminum rods and extruding molds, while aluminum rods are made from aluminum ingots through melting and casting, which is called industrial aluminum profile raw materials; The raw materials will directly affect the performance of industrial aluminum products. 2: Aluminum rod heating: The heating treatment of the aluminum rod must ensure the temperature control. If the temperature is too high or the temperature is too low, it will directly affect the hardness of the final product, so the temperature must be strictly controlled during the heating and cooling process; 3: Mold design : profile is the final product of aluminum rod extruded through die after heating, and the die is a high-precision appliance designed according to the demand, used to extrude profile products of required specifications and cross-section; 4: extrusion: For extrusion production, extrusion temperature is the most basic and most critical process factor. The extrusion speed must be carefully controlled during the extrusion process. 5: profile straightening correction: there will be a certain deviation after the industrial aluminum profile is extruded, and the straightening machine needs to be used for straightening correction after the forming, to correct the newly extruded industrial aluminum profile profile to the required tolerance range Within this, straightening correction must be done with a straightening machine to ensure its accuracy. 6: Artificial aging: The aluminum profile produced by extrusion has low hardness before aging and cannot be used as a finished product. Therefore, in general, it must be aging to increase its strength. 7: Sandblasting + oxidation treatment process: After the extrusion of industrial aluminum profiles, the surface will have obvious stretching lines, and the surface has large micropores and relatively rough, which must be sandblasted. 8: Packaging: due to industry The quality requirements of aluminum profile products are very high, and the overall aesthetics of the appearance are very particular, so the requirements for later packaging are very strict. I believe that seeing this, everyone has their own opinions on the 'industrial aluminum extrusion production process'. If you have any questions about industrial aluminum profile extrusion processing, please consult!

One increasingly popular managerial tactic to improve problem-solving performance of custom aluminium extrusion is to increase the connectedness, or what academics call clustering, of the organization

Get cost effective and professional aluminum window profile manufacturers advice for your solution at Zeyi Aluminum Profiles. Zeyi Aluminum Co., Ltd. expert is your first choice!

This is especially true when Zeyi Aluminum Co., Ltd. have got a global business that's building bridges between manufacturers and customers across the globe.

Zeyi Aluminum Co., Ltd. is the best manufacturer which has rich experience on manufacturing.

One increasingly popular managerial tactic to improve problem-solving performance of custom aluminium extrusion is to increase the connectedness, or what academics call clustering, of the organization

Get cost effective and professional aluminum window profile manufacturers advice for your solution at Zeyi Aluminum Profiles. Zeyi Aluminum Co., Ltd. expert is your first choice!

This is especially true when Zeyi Aluminum Co., Ltd. have got a global business that's building bridges between manufacturers and customers across the globe.

Zeyi Aluminum Co., Ltd. is the best manufacturer which has rich experience on manufacturing.

Custom message