Industrial aluminum production process

by:Zeyi

2021-10-03

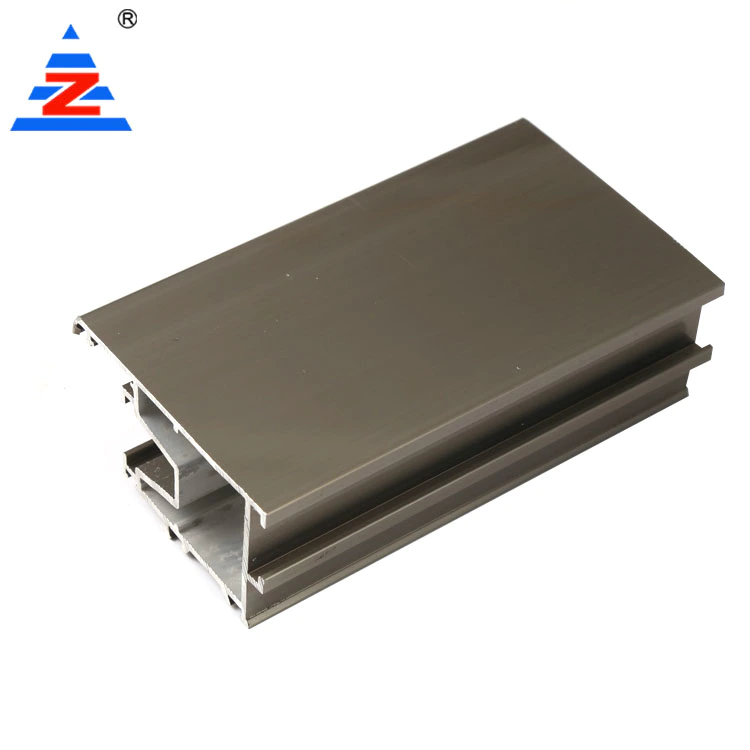

In our daily life, everyone can see industrial aluminum profiles in many places. We know what aluminum profiles look like and what they can be used for, but do you know the production process of industrial aluminum profiles before the finished products appear? ? I believe that everyone is as curious as I am. The steps taken by combining pure aluminum and other metal elements to become the industrial aluminum profile we see before our eyes. Next, let's take a look at the production process of industrial aluminum. The production process of industrial aluminum profiles mainly includes three basic processes: casting, extrusion and coloring. Among them, coloring includes oxidation, electrophoresis coating, fluorocarbon spraying, powder spraying and so on. First of all, it is fusion casting. According to the detailed alloy trademarks that need to be produced, the increase of various alloy components is calculated, and various raw materials are rationally deployed. The prepared raw materials are melted in the melting furnace according to the process requirements, and the slag and gas in the melt are removed through degassing and slagging processes. The molten aluminum is cooled and casted into various specifications of aluminum rods through a deep well casting system under specified casting conditions. Then there is extrusion. First, a mold is planned and manufactured according to the profile product section, and the heated aluminum rod is extruded from the mold to form, and then after heat treatment, an industrial aluminum profile with the same shape as the mold can appear. It should be noted here that the heat treatment criteria of different products of heat-treatable and strengthened alloys will also be different. The last step is coloring. The most important point of coloring is anodizing. The surface of the industrial aluminum profile produced in the first two steps is not strong in corrosion resistance. It must be surface treated by anodizing to increase the corrosion resistance and resistance of aluminum. Abrasiveness, of course, while enhancing the overall performance of industrial aluminum profiles, it also improves the aesthetics of the surface. ————The article comes from the Internet. If there is any infringement, please contact to delete it.

Custom message