Industrial aluminum profile selection is the most critical

by:Zeyi

2021-05-02

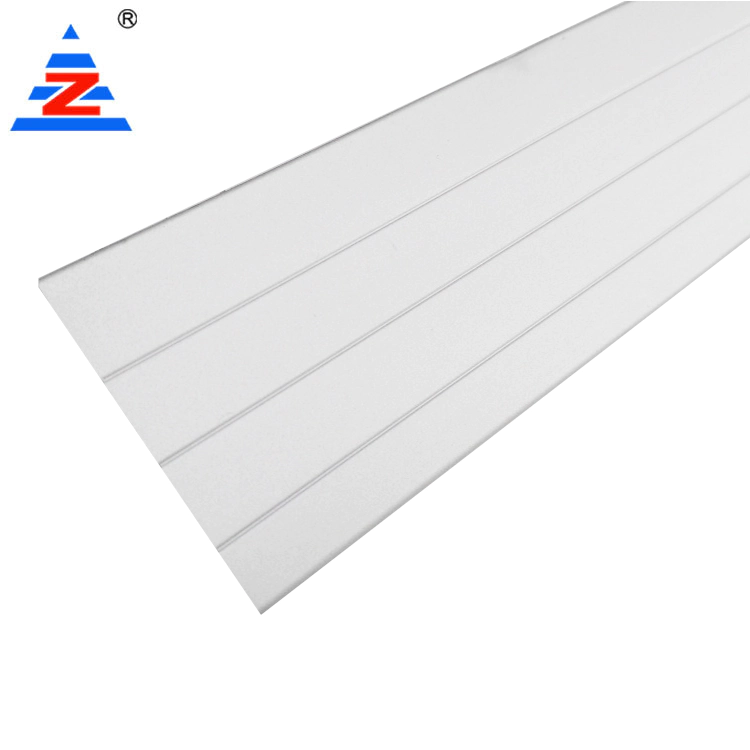

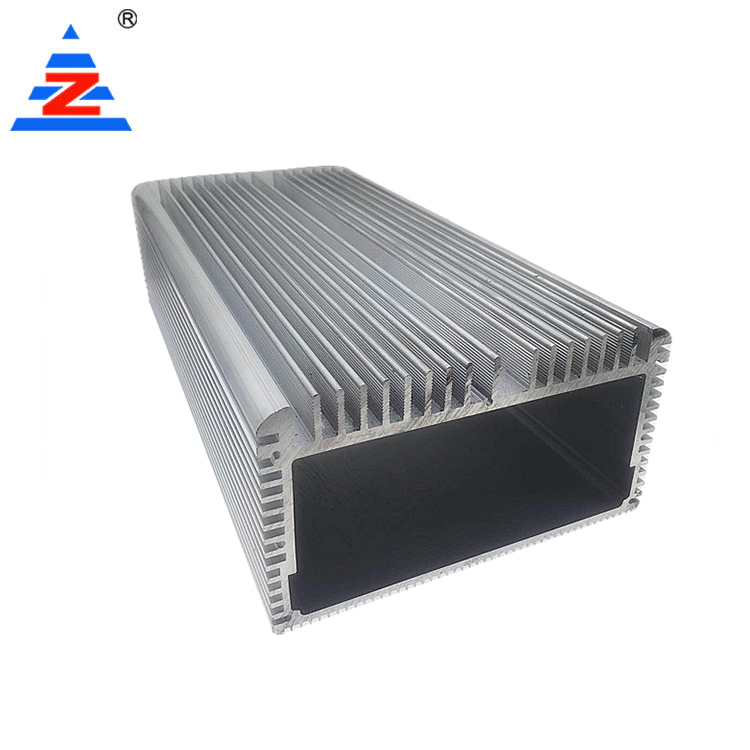

Hardness: Many customers are very concerned when buying aluminum, and the first choice of hardness is directly related to the chemical composition of the alloy. Secondly, different conditions also have a greater impact. From the point of view of the highest hardness that can be achieved, the 7 series, the 2 series, the 4 series, the 6 series, the 5 series, the 3 series, and the 1 series decrease in order. Strength: Strength is an important factor that must be considered during product design. When it is made of aluminum alloy components as components, the appropriate alloy should be selected according to the pressure it bears. Pure aluminum has the lowest strength, while the 2 series and 7 series heat-treated alloys have the highest degree. The hardness and strength have a certain relationship. Corrosion resistance: The corrosion resistance of industrial aluminum profiles includes chemical corrosion and stress corrosion resistance. Generally speaking, pure aluminum of series 1 has the best corrosion resistance, series 5 performs well, followed by series 3 and 6, and series 2 and 7 are inferior. The selection principle of corrosion resistance should be determined according to its use occasion. For high-strength alloys to be used in a corrosive environment, various anti-corrosion composite materials must be used. Machinability: Machinability includes insert forming performance and cutting performance. Because formability is related to state, after selecting aluminum alloy grades, the strength range of various states must be considered. Generally, high-strength materials are not easy to form. Taiguo needs to bend, stretch, and deep-draw the aluminum material. The formability of the material in the annealed state is the best. On the contrary, the formability of the heat-treated material is the worst. Aluminum alloy has poor machinability and better machinability for molds and mechanical parts. On the contrary, low-strength ones have poor machinability. For products that require cutting, such as molds and mechanical parts, the machinability of aluminum alloy is important. Consider factors. Weldability: There is no problem with the weldability of most aluminum alloys, especially some 5 series aluminum alloys, which are specially designed for welding considerations. On the contrary, some 2 series and 7 series aluminum alloys are difficult to weld. Decorative performance: When industrial aluminum profile profiles are used for decoration or some specific occasions, the surface needs to be processed by anodizing and painting to obtain the corresponding color and surface structure. At this time, its decorative properties should be considered, generally In terms of materials with better corrosion resistance, their anodic treatment performance, surface treatment performance, and coating performance are very good. ————The article comes from the Internet. If there is any infringement, please contact to delete it.

As we have known for quite some time, the success of Zeyi in the future will depend greatly on our ability to strike a balance between valuable human insight and interaction with technology.

Helping our customers manage document workflow and increase efficiency through best-in-class custom aluminium extrusion and services. Fostering the growth and development of our employees.

custom aluminium extrusion has its grasp on oversees market also and has a very good repute.

We are proud to be a part of helping you to make healthy choices to last a lifetime. Check out our website to see all aluminum window profile manufacturers custom aluminium extrusion products we offer at Zeyi Aluminum Profiles. If you want to start that road to be better, contact us today!

As we have known for quite some time, the success of Zeyi in the future will depend greatly on our ability to strike a balance between valuable human insight and interaction with technology.

Helping our customers manage document workflow and increase efficiency through best-in-class custom aluminium extrusion and services. Fostering the growth and development of our employees.

custom aluminium extrusion has its grasp on oversees market also and has a very good repute.

We are proud to be a part of helping you to make healthy choices to last a lifetime. Check out our website to see all aluminum window profile manufacturers custom aluminium extrusion products we offer at Zeyi Aluminum Profiles. If you want to start that road to be better, contact us today!

Custom message