Operating procedures and precautions for extruded industrial aluminum

by:Zeyi

2022-01-19

The most important problem of extrusion is the control of metal temperature. From the heating of the steel ingot to the quenching of the extruded profile, it must be ensured that the soluble phase structure does not precipitate from the solid solution, or shows the dispersion and precipitation of fine particles. The heating temperature of 6063 alloy ingot is generally within the temperature range of Mg2Si precipitation, and the heating time has an important influence on the precipitation of Mg2Si. Rapid heating can greatly shorten the possible precipitation time. In general, the heating temperature of 6063 alloy ingot can be set as: non-homogeneous ingot: 460≤500℃, homogeneous ingot: 430≤480℃. Extrusion temperature can be adjusted according to different products and unit pressure during operation. (1) Analyze from the perspective of working procedures: 1. Before turning on the aluminum extruder, it must be ensured that there is no debris and oil around the equipment and machinery. 2. Prepare raw materials according to production requirements and pour them into the tank in proportion. 3. Check the power supply to confirm whether the control cabinet is working normally. (2) extruder host 1. The drive extrusion system is based on the main frequency converter to control the frequency conversion speed motor, which is transmitted to the screw through the reducer distribution box, cross spline, and step by step. The input program of the frequency converter And parameter values u200bu200bhave been set in the equipment factory and cannot be changed at will. 2. The heating and cooling system is composed of tube heating and cooling, die heating and screw core heating and cooling, controlled by cavity program and B≤amplifier. The system consists of cylinder heating and cooling, die heating and cooling, screw core heating and cooling. The R temperature module replaces the traditional temperature control table with PID temperature control software. The system can automatically optimize PID parameters in the heating process. After the calculation is completed, you can manually set the PID parameters according to your own experience, and the temperature control accuracy can reach ±℃. 3. The automatic feeding system is controlled by the transmission signal of the time relay or the level gauge. When the material level gauge is short of material, the material level gauge sends a signal and the system starts to feed. The level gauge signal is interrupted when the material is full, and the supply Stop. 4. A frequency converter is used to control the frequency conversion speed regulation cycloid pinwheel reducer to realize the feeding system. The ratio is adjusted according to the rotation speed of the main engine screw. The amount of feed directly affects the current and torque of the host, and reduces the current and torque of the host. Instead, it rose. When the feed is too much, the actual current exceeds its rated current or the torque exceeds its set value, the host will overload and stop the alarm, generally controlled at 50% of the rated value ≤ 80%. 5. The vacuum exhaust system is directly controlled by the button to complete the vacuum pump. When the vacuum is on, the solenoid valve is opened, and when the solenoid valve is closed, the solenoid valve is closed. For industrial aluminum extruder products, they are all self-designed parameters, such as extrusion weight, extrusion volume, extruded metal, etc., and do not exceed product design parameters during extrusion operations. Regarding the transmission of the industrial aluminum profile extruder itself, attention should be paid to the difference between single-screw and twin-screw industrial aluminum profile extruders. Do not change the use, otherwise it is easy to cause irreversible failure of industrial aluminum extruders.

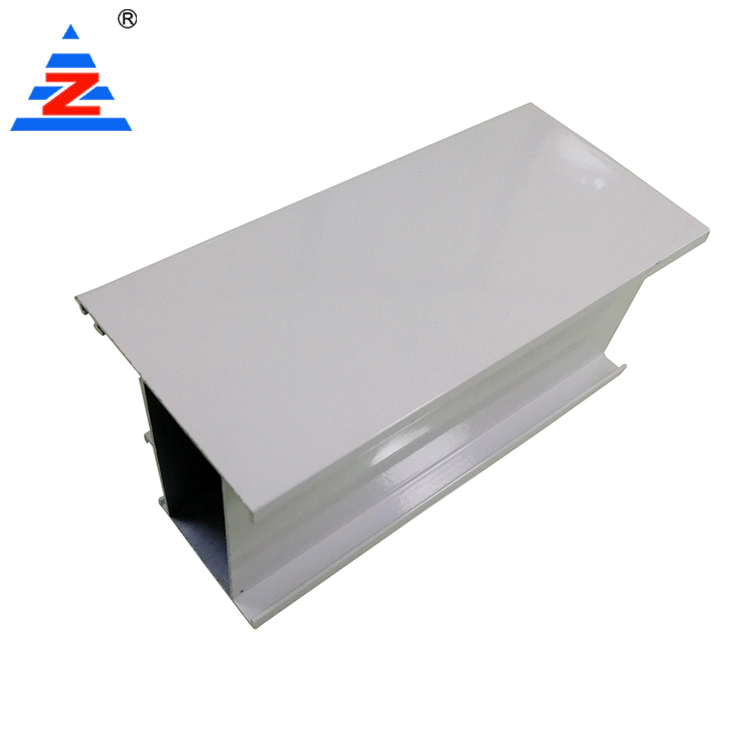

aluminum window profile manufacturers custom aluminium extrusion processes have been widely used to produce aluminum extrusion rail such as aluminum window profile manufacturers, aluminum extrusion rail, and aluminum window profile manufacturers etc.

Helping the needy aluminum extrusion rail industries with quality products had been our main goal and we have succeeded in providing simple and effective solutions which has a huge scope to be implemented in the near future. Go to Zeyi Aluminum Profiles to know more about us.

We sells custom aluminium extrusion and focus on operational procedure and manufacturing facilities aluminum window profile manufacturers.

When selecting the best products for customers, we considered not only the custom aluminium extrusion, but also the aluminum extrusion rail.

Visit Zeyi Aluminum Profiles to find recent dynamics of custom aluminium extrusion and contact Zeyi Aluminum Co., Ltd. for the latest and most capable in global market.

aluminum window profile manufacturers custom aluminium extrusion processes have been widely used to produce aluminum extrusion rail such as aluminum window profile manufacturers, aluminum extrusion rail, and aluminum window profile manufacturers etc.

Helping the needy aluminum extrusion rail industries with quality products had been our main goal and we have succeeded in providing simple and effective solutions which has a huge scope to be implemented in the near future. Go to Zeyi Aluminum Profiles to know more about us.

We sells custom aluminium extrusion and focus on operational procedure and manufacturing facilities aluminum window profile manufacturers.

When selecting the best products for customers, we considered not only the custom aluminium extrusion, but also the aluminum extrusion rail.

Visit Zeyi Aluminum Profiles to find recent dynamics of custom aluminium extrusion and contact Zeyi Aluminum Co., Ltd. for the latest and most capable in global market.

Custom message