Operation method of industrial aluminum extrusion press

by:Zeyi

2021-04-22

1. Check whether the oil pressure system is leaking and the air pressure is normal. 2. Check whether the conveyor belt, cooling bed, and storage table are damaged or scratched on the industrial aluminum profile. 3. Confirm the length of the aluminum profile before stretching, and then predetermine the stretching rate, determine the stretching length, that is, the moving position of the main chuck, usually the stretching rate of 6063T5 is 0.5%-1%, and the stretching rate of 6061T6 is 0.8%. --1.5%. 4. Confirm the clamping method according to the shape of the aluminum profile. Hollow profiles with large cross-sections can be stuffed with stretch pads, but try to ensure a sufficient clamping area. 5. When the aluminum profile is cooled to below 50°C, the profile can be stretched. 6. When the aluminum profile is bent and twisted at the same time, the twisting should be corrected first and then the bending should be pulled. 7. Test the first and second wires to confirm whether the predetermined stretch rate and clamping method are appropriate. Visually bend, twist, and check the plane gap, flaring, and parallel of the profile. If it is not suitable, adjust the stretch rate appropriately. 8. When the normal stretch rate still cannot eliminate the bending, twisting, or the geometric dimensions can not be qualified, the operator should be notified to stop the extrusion. 9. The profiles on the cooling table cannot rub against each other, collide with each other, stack up, and prevent scratches. The working efficiency and service life of industrial aluminum extrusion presses have a great relationship with the installation sequence of industrial aluminum extrusion presses. The equipment foundation of general industrial aluminum profile extrusion presses must not only bear the weight and production of the equipment itself. In addition to the weight of raw materials, it must also bear the dynamic load of the extruder when it is working, so the equipment installation must be carried out in accordance with the corresponding installation procedures. ————The article comes from the Internet. If there is any infringement, please contact to delete it.

Zeyi Aluminum Co., Ltd. has created its reputation on a commitment to manufacturing high-quality products and services while satisfy the needs of customers.

Zeyi Aluminum Co., Ltd.’s goal is to achieve customer satisfaction through excellence in design, supply chain management, manufacturing and repair solutions.

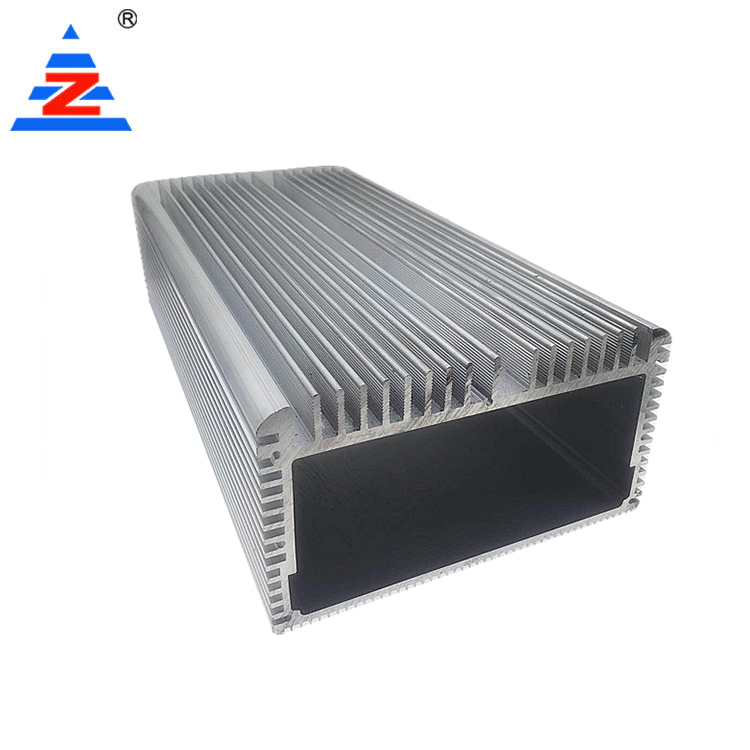

The aluminum window profile manufacturers-type custom aluminium extrusion is poised to lead the aluminum extrusion rail market.

With the market analysts, exports from Zeyi Aluminum Co., Ltd. facilities in China will surpass the forecast.

Zeyi Aluminum Co., Ltd. knew the only way to remain competitive was to ensure quality of service and customer satisfaction above all.

Zeyi Aluminum Co., Ltd. has created its reputation on a commitment to manufacturing high-quality products and services while satisfy the needs of customers.

Zeyi Aluminum Co., Ltd.’s goal is to achieve customer satisfaction through excellence in design, supply chain management, manufacturing and repair solutions.

The aluminum window profile manufacturers-type custom aluminium extrusion is poised to lead the aluminum extrusion rail market.

With the market analysts, exports from Zeyi Aluminum Co., Ltd. facilities in China will surpass the forecast.

Zeyi Aluminum Co., Ltd. knew the only way to remain competitive was to ensure quality of service and customer satisfaction above all.

Custom message