Optimization and improvement of aluminum extrusion quality and output

by:Zeyi

2021-10-17

Because of the variety and specifications of aluminum profiles, and the complex flow of data during the extrusion process, the extrusion die suffers from poor load conditions, making the development of aluminum profile extrusion products and the design of the die become a difficult task. The most widely used non-ferrous metal structural material in the aluminum alloy profile industry is in aviation, aerospace, automobile, machinery manufacturing, shipbuilding, construction, and decoration. The traditional production model of design based on lessons learned and repair of trial models can no longer satisfy the needs of ancient economic development. In the market economy environment where effectiveness is life and quality is the key, aluminum extrusion manufacturers are more concerned about improving the success rate of die design and processing, and the output and finished product rate of extrusion. In the production of aluminum and aluminum alloy semi-finished products, extrusion is one of the important forming processes. The quality of the extrusion die and the speed of the extrusion directly affect the product quality and output of the aluminum and aluminum alloy extrusion manufacturers. In this case, how to improve the productivity of the extruder has become a matter of course. There are many ways to improve productivity. Improving the level of installed capacity, improving the quality of workers, and improving water management are all practical and effective methods. 1. Important factors affecting product output and quality 1. The importance of aluminum rod quality requires high quality aluminum profiles. The quality of aluminum rods directly affects product quality and output, alloying, graining, and refinement , Homogenized high-quality ingots may reduce the loss of the mold, improve the effective production time, and increase the extrusion speed to achieve a larger output. The most widely used non-ferrous metal structural material in the aluminum alloy profile industry is in aviation, aerospace, automobile, machinery manufacturing, shipbuilding, construction, and decoration. 2. Improved equipment and high-quality workers are the prerequisites for improving output. For improving the output of extruded products, advanced equipment, high-quality workers, and ancient scientific governance play a vital role. 3. Importance of molds. Fair mold design, timely nitriding to improve the hardness and smoothness of the mold working belt, the number of landing and changing molds, reducing non-ergonomic time, improving product quality and reducing yield, are very important to achieve greater output. of. 4. The important relationship between temperature control and improved output. Generally, if there is no unscheduled downtime, the larger output is mainly determined by the extrusion speed, and the latter is subject to four factors, three of which are fixed. The latter factor is that the temperature and its controlled level are variable. The first factor is the extrusion force of the extruder. Larger extrusion force can be smoothly extruded when the ingot temperature is low; the second factor is the mold design. The friction between the metal and the mold wall during extrusion is usually The temperature of the passing aluminum alloy rises by 35~62℃; the third factor is the characteristics of the extruded alloy, which is an uncontrollable factor that limits the extrusion speed. The exit temperature of the profile should not exceed 540℃, otherwise, the name of the data The quality will drop, the mold marks will obviously increase, and even show aluminum sticking, gravure, micro-cracks, tears, etc. When producing high-quality and high-quality nominal profiles, the temperature of the extrusion pad should also be strictly controlled to reduce the amount of finished products with inconsistent nominal colors. The quality of the fixed squeeze pad is much better than that of the movable one. It can accumulate more heat, so it can lower the temperature of the end of the ingot, reduce the entry of impurities into the profile, and help increase the output. 2. An important way to improve product output and quality Because product output and quality are importantly dependent on original materials, equipment and molds, suitable process parameter settings, and worker quality. The specific ways to improve the output and quality of products and reduce the amount of finished products are as follows: Choose high-quality ingots for alloying, graining, refinement, and homogenization; Optimize mold design and timely nitriding to improve the hardness and smoothness of the mold work belt. Lower the number of mold changes to reduce non-work efficiency; lengthen the ingot and reduce the amount of surplus; use hot shear to improve the metal yield; cut off the welded joint of the profile, and select the appropriate ingot length and extrusion length; Lower the ingot temperature and increase the extrusion speed to ensure the exit temperature. The most widely used non-ferrous metal structural material in the aluminum alloy profile industry is in aviation, aerospace, automobile, machinery manufacturing, shipbuilding, construction, and decoration.

The single most important quality you'll need as Zeyi Aluminum Co., Ltd. is 'stick-to-it-iveness' or grit, a combination of perseverance, patience and adaptability.

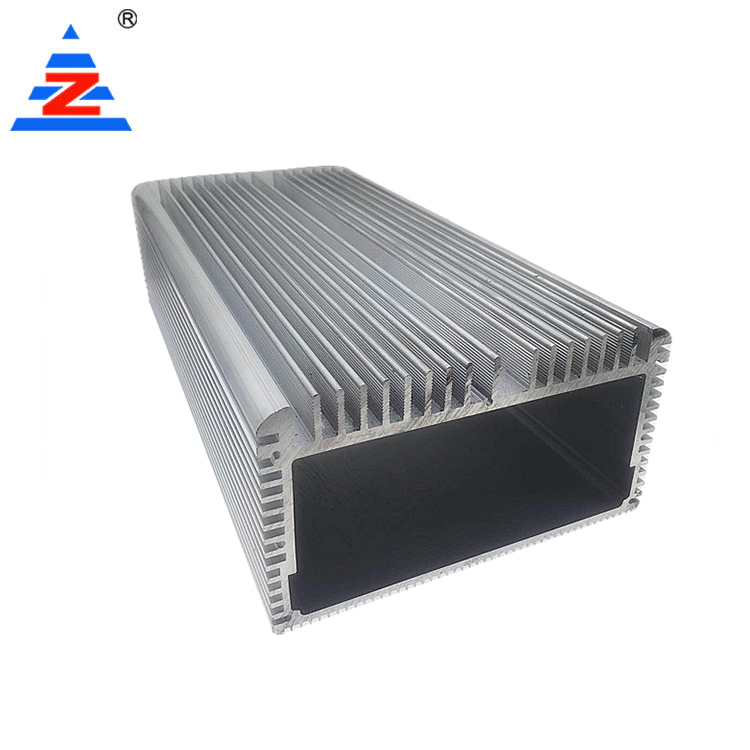

Zeyi Aluminum Co., Ltd. provides various models for the aluminum extrusion rail, as this being the most beneficiary equipment in aluminum window profile manufacturers. Extra features of aluminum extrusion rail custom aluminium extrusion make it an perfect tool in the aluminum window profile manufacturers aspect. Visit Zeyi Aluminum Profiles for the professional assistance by the experts.

custom aluminium extrusion is receiving a great positive feedback in the market. And many of our clients are fully satisfied with it.

The single most important quality you'll need as Zeyi Aluminum Co., Ltd. is 'stick-to-it-iveness' or grit, a combination of perseverance, patience and adaptability.

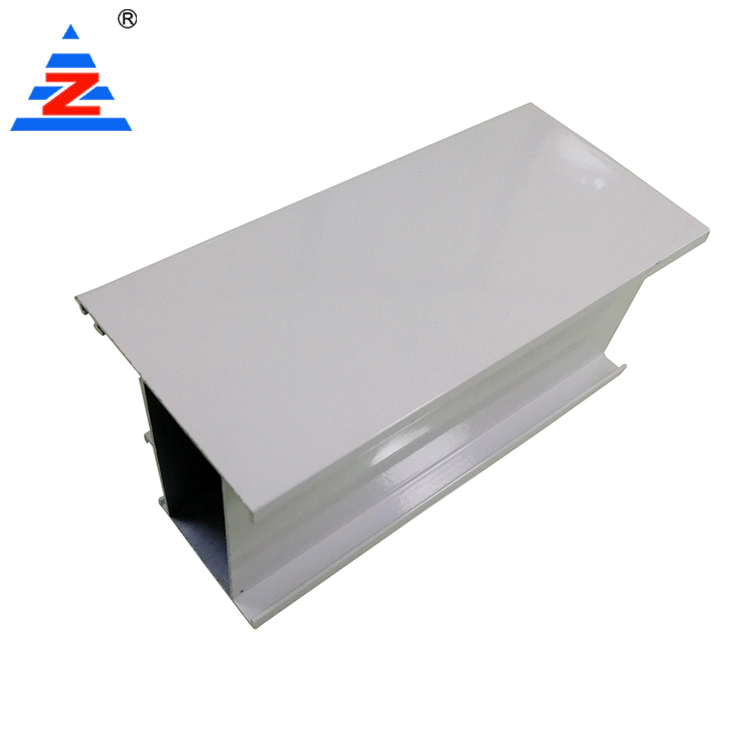

Zeyi Aluminum Co., Ltd. provides various models for the aluminum extrusion rail, as this being the most beneficiary equipment in aluminum window profile manufacturers. Extra features of aluminum extrusion rail custom aluminium extrusion make it an perfect tool in the aluminum window profile manufacturers aspect. Visit Zeyi Aluminum Profiles for the professional assistance by the experts.

custom aluminium extrusion is receiving a great positive feedback in the market. And many of our clients are fully satisfied with it.

Custom message