Surface treatment technology of aluminum profile electrophoresis coating

by:Zeyi

2021-06-10

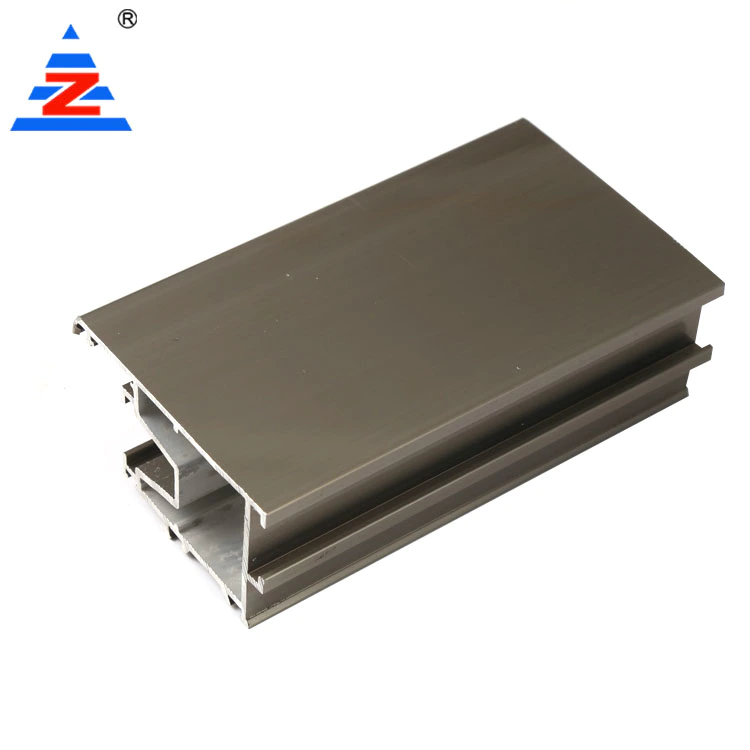

The traditional surface treatment technology of aluminum profile is oxidation, coloring and closing treatment. The aluminum after these surface treatments is easy to corrode and has poor durability when exposed to acid rain or marine environment. Therefore, in the early 1970s, aluminum profile manufacturers tried to use paint coating to further build the decoration performance and service life of aluminum profiles. Currently, electrophoretic coating, powder coating and fluorocarbon spraying have been successfully applied to aluminum profiles. . Among them, the surface treatment technology of aluminum profile electrophoresis painting is one of the most applicable technologies in the development direction. Aluminum profile surface treatment electrophoretic painting: Electrophoretic painting is based on anodizing, and the oxide film is covered with a water-soluble acrylic paint film through the action of electrophoresis. Therefore, the surface film of electrophoretic aluminum profile is a composite film of anodized film and water-soluble acrylic paint film. It has better corrosion resistance, weather resistance and wear resistance than anodic oxidation, and the surface of the aluminum profile is smoother and more beautiful. The principle of electrophoretic coating for surface treatment of aluminum profiles: The principle of electrophoretic coating was invented in the late 1930s, but the development of this technology and its industrial application was after 1963, and electrophoretic coating was developed in the past 30 years. A special coating film formation method is the most practical construction process for water-based coatings. It has the characteristics of water solubility, non-toxicity, and easy automatic control. Aluminum can be directly electrophoresed after pre-treatment and washing. The electrophoretic coating has high transparency, high decoration and can highlight the metallic luster of the aluminum profile itself. Therefore, the use of electrophoretic paint has been continuously increased in the construction of aluminum profiles, and the electrophoretic coating has been rapidly applied. It is widely used in industries such as automobiles, building materials, hardware, and home appliances. Electrophoretic profiles are more decorative than spray paint and powder spraying. Electrophoretic surface treatment styles are diverse, with extraordinary texture, classic simplicity and other different styles. The colors include electrophoretic silver, electrophoretic champagne and frosted silver. Customers can choose different styles according to their needs. A model of high-end and luxurious aluminum profiles, aluminum profile manufacturers with electrophoresis production lines are an important manifestation of the comprehensive technical level. Electrophoresis coating production process:

If you have a aluminum window profile manufacturers business, be sure to choose a from Zeyi Aluminum Co., Ltd.. After all, you need quality equipment in order to provide your customers with quality service.

If you're interested in buying a of high quality and affordable price, let Zeyi Aluminum Co., Ltd. at Zeyi Aluminum Profiles be your guide to the best shopping experience.

The more people who do a certain thing, the more likely others are to do it as well. When Zeyi can demonstrate their popularity or satisfaction across a wide customer base, other consumers are more likely to buy in as well.

If you have a aluminum window profile manufacturers business, be sure to choose a from Zeyi Aluminum Co., Ltd.. After all, you need quality equipment in order to provide your customers with quality service.

If you're interested in buying a of high quality and affordable price, let Zeyi Aluminum Co., Ltd. at Zeyi Aluminum Profiles be your guide to the best shopping experience.

The more people who do a certain thing, the more likely others are to do it as well. When Zeyi can demonstrate their popularity or satisfaction across a wide customer base, other consumers are more likely to buy in as well.

Custom message