Surface Wastewater Treatment Technology of Industrial Aluminum Profiles

by:Zeyi

2021-11-27

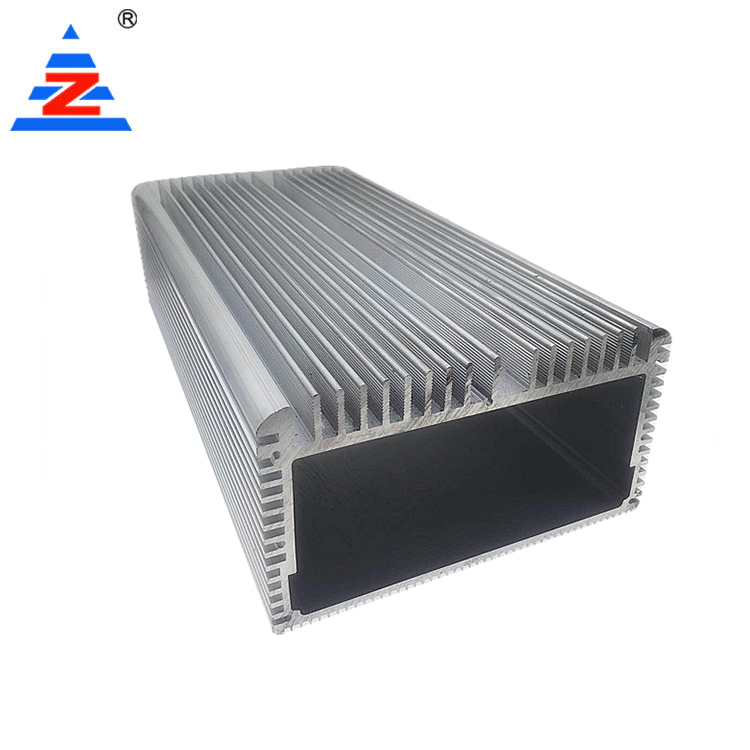

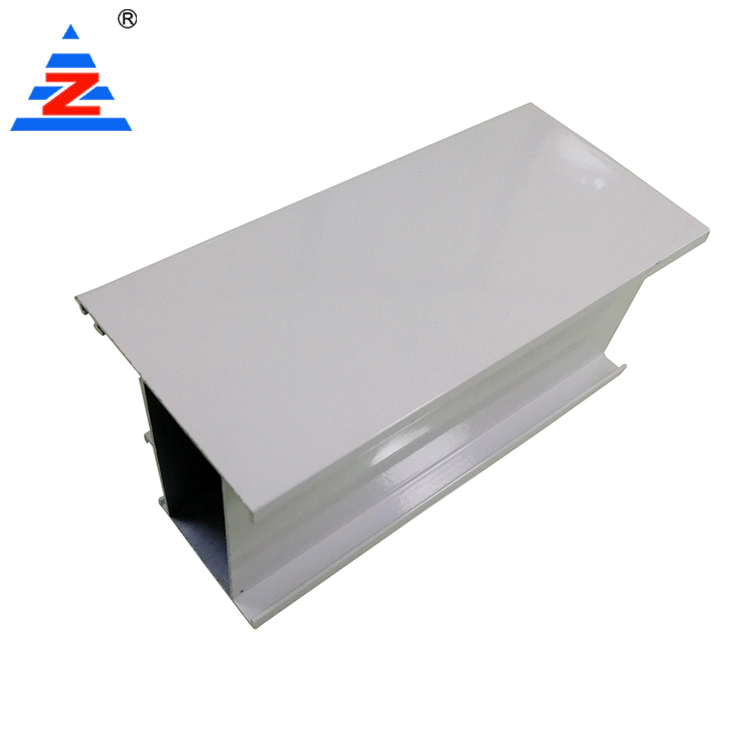

profile surface wastewater treatment technology profile will produce a lot of waste water when researching surface treatment, and there are certain harmful substances in the waste water to be discharged. If it is not analyzed and processed, it will cause students to certain social and environmental factors. Impact, then what are the wastewater treatment data technologies for the wastewater treatment of industrial aluminum profiles in China, the following is our specific understanding. Products made of top ten brands of aluminum and other alloy elements. Usually it is processed into castings, forgings, foils, plates, strips, tubes, rods, profiles, etc., and then cold bending, sawing, drilling, assembling, coloring and other processes. The main metal element is aluminum, and some alloying elements are added to improve the performance of aluminum. All-aluminum household aluminum panels on both sides, the PVC core filled in the middle of the PVC panels on the market, usually have a density value of about 1.4-1.8 (the smaller the density value, the better the quality). Door and window aluminum door and window materials, the material connected to the wall. Its main feature is that the surface where it meets the wall is mostly flat, which is fixed on the wall and cannot be moved. 1. The source and type of domestic wastewater for aluminum profile surface information treatment. Wastewater treatment. The aluminum surface pretreatment is degreased and washed with water, acid washed with water after oxidation, colored Ni2+, medium Sn2+, acid washing water, and alkaline washing water after ion exchange. After the alkaline etching, the amount of water contained, the acid washing acid electrophoresis generator after the acid etching, and the waste alkaline electrophoretic paint of the waste water is small. Mixed acid wastewater, containing Al3+, Ni2+, medium Sn2+, SN4+, sodium ion, (Ⅲ) and other cations and SO42-, F-, NO3-, chloride ion, AlO2-, AC- other anions, surfactants and Acrylic and organic resins. Waste liquid and waste are produced in degreasing waste sulfuric acid, waste sulfuric acid and nitric acid waste liquid produced by oxidation, coloring waste, waste liquid acrylic acid electrodeposition paint production, which leads to clogging containing nickel+, F- and the like. 2. Ways to reduce the discharge of wastewater and waste liquid from enterprises. The ways to reduce waste water and waste liquid are to reasonably control the water control time and control the filling angle to reduce the amount of tank liquid. Try to use two-stage and three-stage countercurrent rinsing to reduce water consumption. The washing water after acid etching and degreasing is used for washing after alkali corrosion, and the washing water after oxidation is used for washing after acid etching and degreasing. In addition, in order to reduce or avoid the discharge of waste water and waste tank liquid, the production line should design and use various recovery devices, such as acid corrosion recovery device, alkali corrosion recovery device, anodized aluminum removal device, coloring liquid RO recovery device, electrophoretic paint RO Recycling devices, the use of these recycling devices can reduce the amount of waste water and waste liquid discharge to a greater limit, and also greatly reduce the production cost. 3. Principles and methods of wastewater treatment for aluminum profile surface treatment The aluminum surface produced by wastewater treatment, containing nickel, medium Sn2+, F- and other small harmful anions and cations, is mainly acidic wastewater, and acid-alkali treatment. The wastewater is usually acidic, and alkali is added to adjust the pH to about 78.5. And, while in the cations Al3+, Ni2+, Sn2+, Cr3+ process, etc., hydroxide precipitates are formed. After neutralization and sedimentation in the wastewater flocculation tank, the metering pump is used to pump into the well at the same time to dissolve the polyamide and the wastewater flocculant. The solidified wastewater enters the sedimentation tank. The swash plate sedimentation method is sedimentation, flotation, centrifugal sedimentation, etc., believe It is more stable to use centrifugal sedimentation, through sedimentation, enter and discharge the overflow outlet from the tank or overflow the upper supernatant for storage and reprocessing. After analyzing the above-mentioned data processing, the wastewater can be discharged up to the standard. If the production wastewater is to be reused, the wastewater technology at this time can be processed by the RO device system after coarse filtration to remove excess anions, cations, and organic matter. The pH value of the water at the time may be low, and it can be found that the reuse standard is reached after the adjustment of the structure of the exchange control device between anion and cation. The sludge produced by the sedimentation development is regularly discharged into the sludge pond, and after being treated by a plate-type cake press or a belt-type dehydrator, it becomes a Chinese industrial waste residue and is sent to an industrial waste residue treatment plant.

are an important part of the society and they come in handy in any place where there are aluminum window profile manufacturers in need of aluminum extrusion rail.

Zeyi Aluminum Co., Ltd. is a reliable company that offers wonderful . In addition, the company also provides related components to make it more efficient. To know more, go to Zeyi Aluminum Profiles.

In terms of custom aluminium extrusion, why is it different than other production? How does it fit a true need or desire for your requires? Is it simple to use? Make life easier?

With the market analysts, exports from Zeyi Aluminum Co., Ltd. facilities in China will surpass the forecast.

are an important part of the society and they come in handy in any place where there are aluminum window profile manufacturers in need of aluminum extrusion rail.

Zeyi Aluminum Co., Ltd. is a reliable company that offers wonderful . In addition, the company also provides related components to make it more efficient. To know more, go to Zeyi Aluminum Profiles.

In terms of custom aluminium extrusion, why is it different than other production? How does it fit a true need or desire for your requires? Is it simple to use? Make life easier?

With the market analysts, exports from Zeyi Aluminum Co., Ltd. facilities in China will surpass the forecast.

Custom message