What are the advantages of all kinds of aluminum tubes

by:Zeyi

2021-06-25

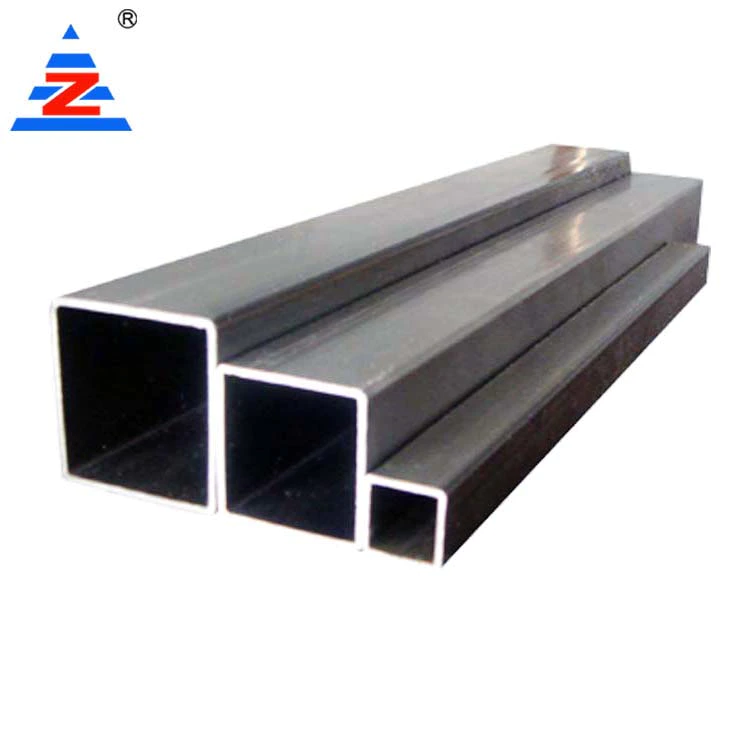

We often see all kinds of engineering constructions in cities, and all kinds of aluminum tube engineering constructions have already surpassed many people's industrial development. This is related to my urbanization construction. During the construction process, many common industrial products came in handy. One of the most common applications is aluminum pipes. Is the price of such products high? For business operators, if the unit price is a little bit higher, it will bring greater economic pressure to themselves. It can be seen that the price has always been at a relatively low level, so it is indeed a good way to save money for those who need to use the product in large quantities. So why? Now the productivity is further liberated, so the ultra-high production efficiency directly lowers the price of the product, and the aluminum tube is actually a good example, so the low price is born like this, so the low price will not affect the quality What? No, this product also has different brands, but the product quality of each brand is almost the same. After all, under the same formula, it is difficult to increase the distance between each other. It can be seen that the big advantage is cost-effectiveness. Very high. For many large companies now, such products are indispensable. The occurrence of stress corrosion is the result of the joint action of tensile stress and corrosive media, and both are indispensable. By performing shot peening treatment (shot glass shot) on the inner and outer surfaces of the thick-walled aluminum tube, a high residual compressive stress can be generated on the surface of the material. According to the measurement, the surface compressive stress can reach 850Mpa and the residual compressive stress can offset the tensile stress during work. Reducing the overall stress level is beneficial to the prevention of stress corrosion. It is beneficial to the categories and basic principles of aluminum pipes: in underground waterproofing, concrete joints are a key part of anti-seepage. In construction projects, consideration is often given to the actual situation and actual location. Use waterstop, waterstop, sealant, borehole grouting and other methods to develop the types and basic principles of anti-aluminum pipes: in underground waterproofing, concrete joints are a key link in anti-seepage, and construction projects are based on reality. Conditions and actual location considerations often use water stop tapes, water stop strips, sealants, drilling grouting and other methods to prevent and deal with. With the advancement of underground waterproofing technology, in recent years, this new type of prevention and repair material for full-section pre-embedded aluminum pipes has made rapid progress. Next, I will mainly explain the types and basic principles of full-section aluminum pipes. Full-section pre-embedded aluminum pipes for concrete joints are divided into single-use aluminum pipes (stainless steel spring frame aluminum pipes) and repeatable aluminum pipes (hard plastic or hard rubber frames). The stainless steel spring frame aluminum tube is composed of a stainless steel spring frame wrapped with a special non-woven filter cloth, and the outside is covered with a polyester mesh. Full-section aluminum pipe is a waterproof plugging material used to seal concrete construction joints, cold joints, pipe seepage, ground walls, etc. It consists of three parts: aluminum pipes, grouting pipes and grouting liquid. The construction joints are pre-buried and waterproof. system. In the grouting process, the filter cloth functions as a reverse valve, which can make the grouting liquid leak into the joint concrete under the corresponding grouting pressure, play a plugging and sealing function, and prevent particles such as sand and dust outside the aluminum pipe from entering. To the aluminum pipe causes the aluminum pipe to be blocked. The tube body of the rigid plastic or hard rubber skeleton aluminum tube is evenly provided with 4 outlet holes, the groove of the tube is covered with a foam strip that functions as a one-way switch, and the outer layer is wrapped by a polyester mesh. When grouting, the grouting liquid with pressure will compress the foamed strips, so that the grouting liquid can be injected into the gap between the concrete construction joints, and it plays a role of grouting to stop leakage. After the grouting construction is completed, the aluminum tube can be cleaned in a special way, and the remaining liquid in the tube can be drawn out by vacuuming, so that the foaming strip can be automatically closed to prevent the outside liquid from flowing back into the aluminum tube. When water seepage occurs, the aluminum tube can still be used to carry out pressure leakage.

The point for Zeyi Aluminum Co., Ltd. is that managerial processes are as important as other inputs in production and can create significant competitive advantage.

Zeyi Aluminum Co., Ltd. is committed to attracting, developing, and keeping a diverse work force that reflects the nature of our global business.

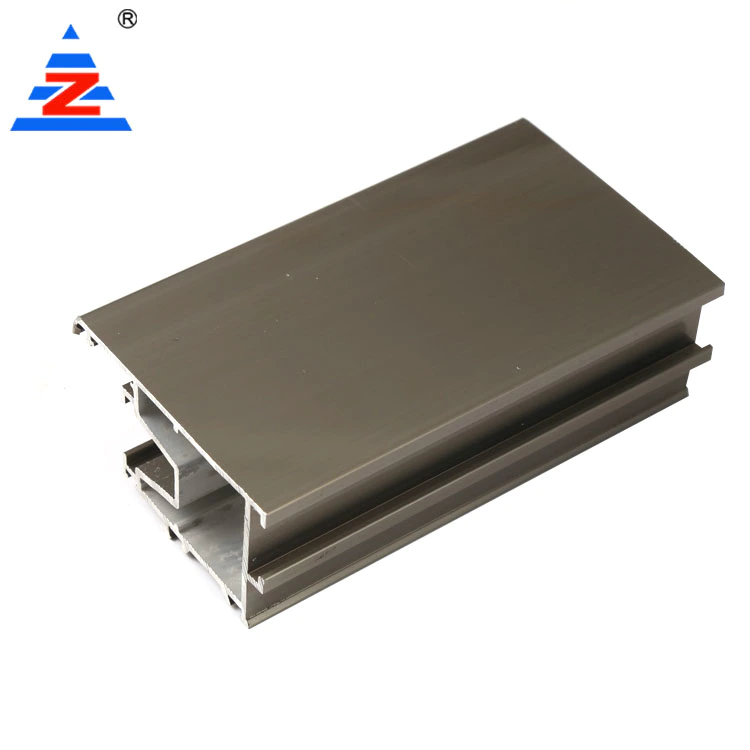

custom aluminium extrusion provider at Zeyi Aluminum Profiles offers a wide variety of in many options. quality is absolutely ensured if you choose us. welcome to visit our factory.

The point for Zeyi Aluminum Co., Ltd. is that managerial processes are as important as other inputs in production and can create significant competitive advantage.

Zeyi Aluminum Co., Ltd. is committed to attracting, developing, and keeping a diverse work force that reflects the nature of our global business.

custom aluminium extrusion provider at Zeyi Aluminum Profiles offers a wide variety of in many options. quality is absolutely ensured if you choose us. welcome to visit our factory.

Custom message