What are the advantages of powder coating surface treatment for aluminum profiles?

by:Zeyi

2021-06-11

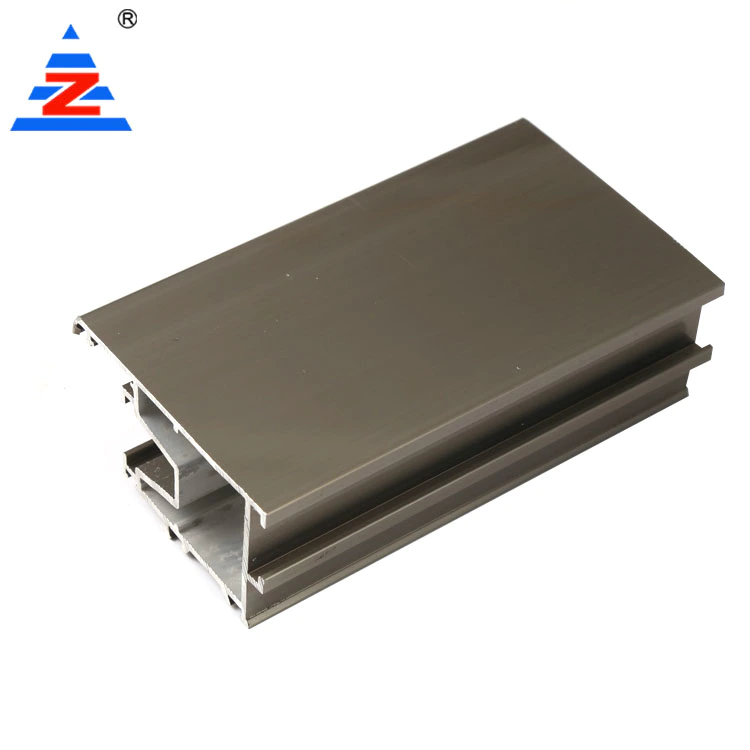

Powder spraying is the use of powder spraying equipment (electrostatic spray gun) to spray powder coating on the surface of the workpiece. Under the action of static electricity, the powder will be uniformly adsorbed on the surface of the workpiece to form a powder coating; the powder coating is baked at high temperature Baking, leveling and curing, it becomes the final coating with different effects (different effects of powder coatings); the spraying effect of powder spraying is better than the spraying process in terms of mechanical strength, adhesion, corrosion resistance and aging resistance, and the cost is also Under the same effect of spray paint. The surface treatment methods of aluminum profiles generally have three treatment methods: anodizing, electrophoretic coating and powder spraying. Each method has its own advantages and occupies a considerable market share. Aluminum profile powder spraying has the following significant advantages: 1. The process is relatively simple, mainly due to the improvement of the automatic accuracy of the main equipment during the production process, and the microcomputer control of some main technical parameters can be achieved, which effectively reduces the difficulty of process operation. At the same time, the auxiliary equipment is greatly reduced; 2, the yield rate is high, under normal circumstances, if various measures are appropriate, the production of unqualified products can be controlled to the greatest extent; 3, the energy consumption is significantly reduced, in the ordinary anodizing, electrophoretic coating In the production process, water and electricity consumption is quite large, especially in the oxidation process. The output current of the rectifier can reach between 8000~11000a, and the voltage is between 15~17.5v. In addition to the heat consumption of the machine itself, it needs to be continuously cooled with circulating water, and the electricity consumption per ton is often about 1000 degrees. At the same time, the reduction of auxiliary facilities can also reduce some electricity consumption; 4, the pollution to water and the atmosphere is reduced, caustic soda, sulfuric acid and other liquid organic solvents are no longer used, reducing water and air pollution, and effectively improving aluminum profiles and As an environmentally friendly product, the competitive strength of plastic steel profiles has correspondingly reduced some production costs; 5. The labor intensity of workers has been significantly reduced. Due to the use of automated assembly line operations, the feeding method and the use of fixtures have been significantly simplified, which has improved production efficiency , It also reduces labor intensity; 6. The surface quality requirements of the wool are significantly reduced. The powder coating can completely cover the extrusion lines on the surface of the profile, conceal some of the defects on the surface of the aluminum profile, and improve the surface quality of the finished aluminum profile. 7. Compared with other surface treatment films, some physical indexes of the coating film are significantly improved, such as hardness, abrasion resistance, and acid resistance, which can effectively extend the service life of aluminum profiles. Powder spraying uses powder coatings, and electrostatic spraying is used in the process. The friction spray gun is used to make the powder particles carry a positive charge when they are sprayed out of the gun body and contact the negatively charged profile. Electrostatic adsorption, then high temperature curing. It also enhances the adsorption strength of the paint and prevents the paint film from falling off. In addition, compared with the traditional paint process, the advantages of powder coating are: 1, high efficiency: because it is a one-time film formation, it can increase productivity by 30-40%; 2, energy saving: reduce energy consumption by about 30%; 3, less pollution :No organic solvent volatilization (not containing harmful gases such as toluene and xylene in paint coatings); 4, high coating utilization rate: up to 95%, and the powder can be used multiple times after recycling; 5, good film performance: once The film-forming thickness can reach 50-80μm, and its adhesion, corrosion resistance and other comprehensive indicators are better than the paint process; 6, low yield: before curing, it can be re-sprayed twice. There are many types of powder coating processes, and two common ones are electrostatic powder spraying and dipping. From the perspective of the process itself, it has a fairly high technological composition, and the deployment of paints of different colors to produce decorative effects of different colors is more in line with the needs of interior decoration, and it is also in line with the trend of aluminum profiles in the construction industry to develop indoors. Consistent. In particular, the combined use of sprayed profiles and thermally insulated bridges makes it a more fashionable trend, giving powder-coated aluminum profiles more room for development, and they cannot be replaced by aluminum profiles produced by other processing methods.

Zeyi Aluminum Co., Ltd. has an array of branches in domestic for servicing customers with high-quality products.

Looking for someone to handle your custom aluminium extrusion aluminum window profile manufacturers needs? Check out Zeyi Aluminum Profiles today for more information.

When you choose to buy instead of aluminum extrusion rail, the money you save may allow you to buy multiple other necessities, more than you had initially planned on buying.

To find a qualified at reasonable price, contact Zeyi Aluminum Co., Ltd. at Zeyi Aluminum Profiles, a professional provider and tell them what you envision for your custom aluminium extrusion.

There are different types of , mainly aluminum window profile manufacturers and aluminum extrusion rail.

Zeyi Aluminum Co., Ltd. has an array of branches in domestic for servicing customers with high-quality products.

Looking for someone to handle your custom aluminium extrusion aluminum window profile manufacturers needs? Check out Zeyi Aluminum Profiles today for more information.

When you choose to buy instead of aluminum extrusion rail, the money you save may allow you to buy multiple other necessities, more than you had initially planned on buying.

To find a qualified at reasonable price, contact Zeyi Aluminum Co., Ltd. at Zeyi Aluminum Profiles, a professional provider and tell them what you envision for your custom aluminium extrusion.

There are different types of , mainly aluminum window profile manufacturers and aluminum extrusion rail.

Custom message