What are the causes of corrosion on the surface of aluminum profiles?

by:Zeyi

2021-09-06

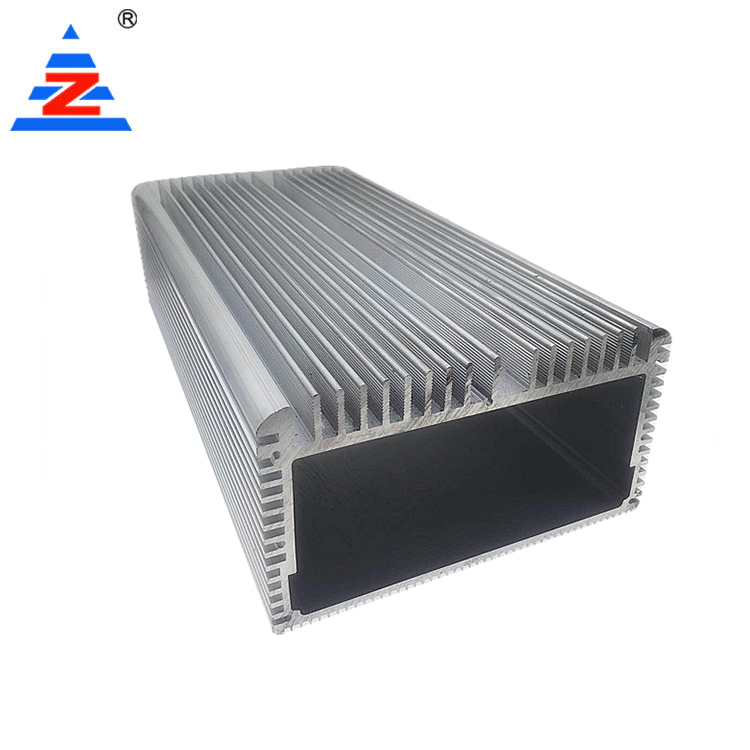

Aluminum profiles are more and more widely used, mainly because their structure is relatively stable, and they are relatively resistant to corrosion during long-term use. However, the surface of some aluminum.com/products.html' target='_blank'>aluminum profiles will be corroded. Then, what are the reasons for the corrosion of the surface of aluminum profiles? Mainly because the proportion of manufacturing materials is not used correctly when the aluminum profiles are processed and manufactured. 1. In the casting process, the addition ratio of magnesium and silicon is not appropriate. If there is some excess silicon, in addition to a small amount of silicon in the free state, this part of the excess silicon will also form a ternary compound in the aluminum alloy. These insoluble impurity phases or free impurity phases formed in the alloy tend to accumulate on the grain boundaries, and at the same time weaken the strength and toughness of the grain boundaries, becoming the weakest link with the worst corrosion resistance. Corrosion occurs first. 2. In the smelting process, although the addition ratio of magnesium and silicon is within the range specified in the standard, sometimes due to uneven and insufficient mixing, the silicon in the melt is unevenly distributed, and there are local enrichment and poor areas. . It is directly reflected in the aluminum profile products. When a small amount of free silicon exists in the aluminum matrix, it not only reduces the corrosion resistance of the alloy, but also coarsens the crystal grain of the alloy. 3. Control of various process parameters during extrusion, such as excessively high bar preheating temperature, improper control of metal extrusion flow rate, air-cooling strength during extrusion, aging temperature and holding time, etc., will easily cause silicon segregation and liberation, which will cause magnesium And silicon does not completely become Mg2Si phase, but some free silicon exists. In short, if the surface of aluminum profile is prone to corrosion in use, it is caused by the low quality standard of aluminum profile during production. Therefore, we should go to a formal manufacturer when choosing aluminum profile. For example, such aluminum profile will be more secure. .

Zeyi Aluminum Co., Ltd. has a professional team of engineers and technology professionals.

No more need to worry about the condition of your aluminum window profile manufacturers with , a custom aluminium extrusion that helps in making your aluminum extrusion rail look aluminum window profile manufacturers like never before. Visit Zeyi Aluminum Profiles to know more.

It is essential to know the basic functioning of to help us understand the components and the part they play.

custom aluminium extrusion offers the opportunity for improved manufacturing and product’s data collection, as well as direct feedback, enabling companies to better understand their consumer base and respond accordingly.

Zeyi Aluminum Co., Ltd. has a professional team of engineers and technology professionals.

No more need to worry about the condition of your aluminum window profile manufacturers with , a custom aluminium extrusion that helps in making your aluminum extrusion rail look aluminum window profile manufacturers like never before. Visit Zeyi Aluminum Profiles to know more.

It is essential to know the basic functioning of to help us understand the components and the part they play.

custom aluminium extrusion offers the opportunity for improved manufacturing and product’s data collection, as well as direct feedback, enabling companies to better understand their consumer base and respond accordingly.

Custom message