What are the causes of cracks in industrial aluminum profiles

by:Zeyi

2021-08-21

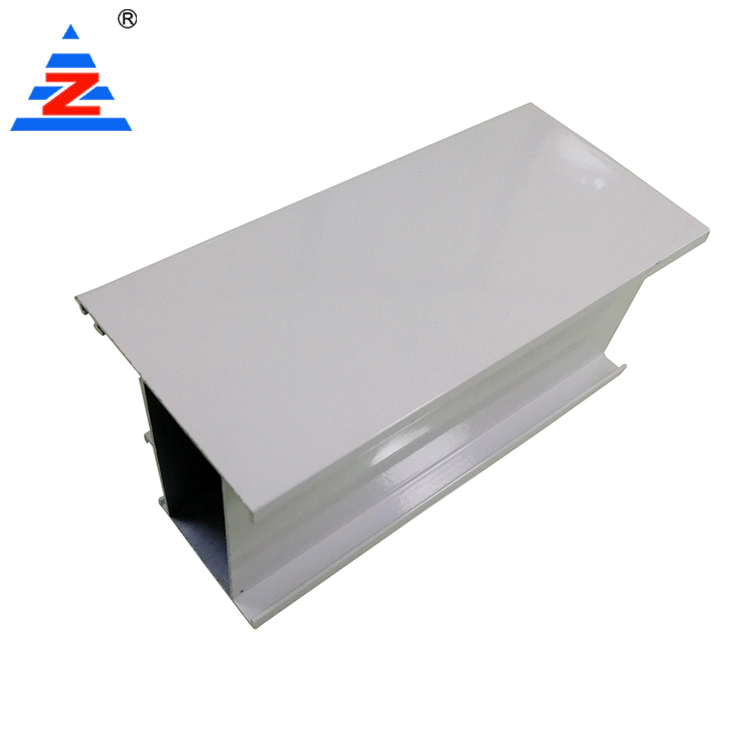

With the large-scale application and popularization of industrial aluminum profile profiles, this lightweight and strong load-bearing industrial aluminum profile alloy profile has received everyone’s praise, but in use, some aluminum profiles will have cracks on the surface. What is this? What is the cause? First, the extrusion temperature of aluminum profile is too high, the tensile strength of the metal surface decreases, and cracks occur under the action of friction; Second, the metal surface is subjected to additional tensile stress due to friction, when additional tension is applied When the stress is greater than the tensile strength of the surface metal, cracks will occur; third, when the extrusion speed of the aluminum profile is too fast, the additional tensile stress on the surface of the metal will increase and cracks will occur in the profile. The “causes of cracks in industrial aluminum profile profiles” is briefly introduced here. In fact, it can be avoided by strictly controlling the extrusion process parameters of aluminum profiles to ensure reasonable exit speed and exit temperature. If you have any questions, please contact us!

What are the technical requirements for the factory in the custom processing of industrial aluminum profiles

Most of the industrial aluminum profiles on the market can meet people's needs. Some factories and enterprises need to customize some aluminum profiles according to their own use, such as: frames, flow tables, industrial walking platforms, etc. The technology has certain requirements. What are the requirements for the aluminum profile processing plant for custom processing? 1. Drawing: The technicians have a certain understanding of the customer’s product use and site, and then draw a sample drawing according to the customer’s requirements Where there are unreasonable requirements, feasible suggestions should be given in time. 2. Processing: Aluminum profile processing requires cutting, drilling, etc., the surface of the aluminum profile must be smooth and free of burrs, the cutting must be precise, and the size error between the product and the sample must be small. 3. Packaging: After processing, the aluminum profile needs to be packaged. When packaging the aluminum profile, wipe the aluminum scraps on the surface of the aluminum profile, handle it with care, avoid bumps, and wrap the aluminum profile with a protective film for logistics delivery. The above is what the editor wants to talk about. If you don't know anything, please consult the editor!

Zeyi Aluminum Co., Ltd. has created a professional team which contained with a numbers of engineers and technology experts.

Zeyi Aluminum Co., Ltd. strives to reflect the highest ethical standards in our relationships with members, providers, and shareholders.

Zeyi Aluminum Co., Ltd. employs a group of professional staff, enhancing the function of custom aluminium extrusion.

What are the technical requirements for the factory in the custom processing of industrial aluminum profiles

Most of the industrial aluminum profiles on the market can meet people's needs. Some factories and enterprises need to customize some aluminum profiles according to their own use, such as: frames, flow tables, industrial walking platforms, etc. The technology has certain requirements. What are the requirements for the aluminum profile processing plant for custom processing? 1. Drawing: The technicians have a certain understanding of the customer’s product use and site, and then draw a sample drawing according to the customer’s requirements Where there are unreasonable requirements, feasible suggestions should be given in time. 2. Processing: Aluminum profile processing requires cutting, drilling, etc., the surface of the aluminum profile must be smooth and free of burrs, the cutting must be precise, and the size error between the product and the sample must be small. 3. Packaging: After processing, the aluminum profile needs to be packaged. When packaging the aluminum profile, wipe the aluminum scraps on the surface of the aluminum profile, handle it with care, avoid bumps, and wrap the aluminum profile with a protective film for logistics delivery. The above is what the editor wants to talk about. If you don't know anything, please consult the editor!

Zeyi Aluminum Co., Ltd. has created a professional team which contained with a numbers of engineers and technology experts.

Zeyi Aluminum Co., Ltd. strives to reflect the highest ethical standards in our relationships with members, providers, and shareholders.

Zeyi Aluminum Co., Ltd. employs a group of professional staff, enhancing the function of custom aluminium extrusion.

Custom message