What are the colors of industrial aluminum profiles

by:Zeyi

2021-08-03

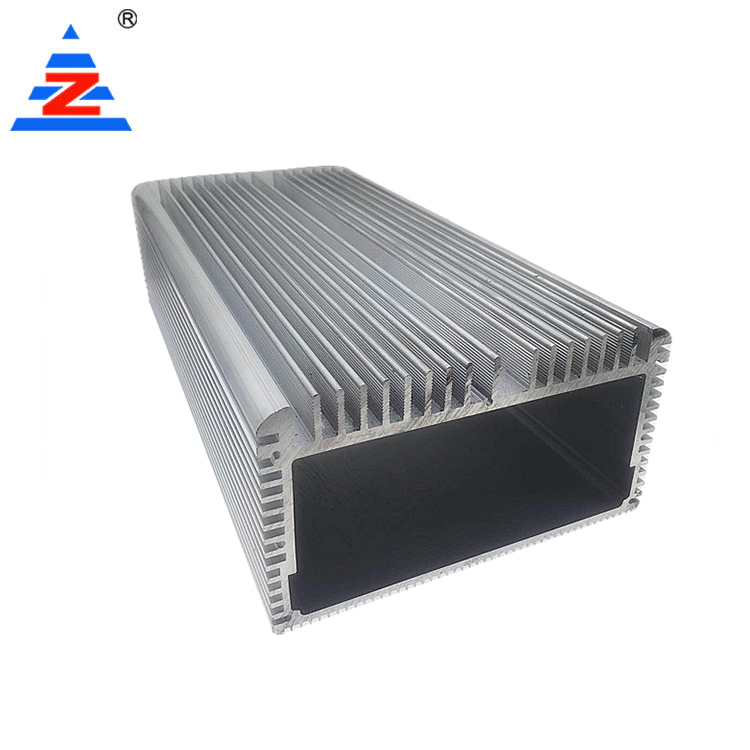

To know the colors of industrial aluminum profiles, we first need to have a basic understanding of industrial aluminum profiles. profiles are aluminum rods that are melted and extruded to obtain aluminum materials with different cross-sectional shapes. Its mechanical properties are related to the application domain and the proportion of alloys added. So what are the colors of industrial aluminum profiles? First of all: there are three production processes for industrial aluminum profiles: casting, extrusion and coloring. Coloring mainly includes: oxidation coloring, electrophoretic coating, fluorocarbon spraying, powder coating, wood grain transfer process. And use a common electrochemical aluminum electrophoresis coating aluminum for the surface treatment of aluminum: secondly: aluminum profiles are generally silver-white, and a small amount of black aluminum profiles; if there is no requirement, it is silver-white. Generally, the default of aluminum profile manufacturers is silver-white profiles; above is the introduction of 'What colors are available in industrial aluminum profiles'.

3 methods for correct coloring of industrial aluminum profiles

Aluminum profiles with better quality are all subject to coloring. Coloring can not only improve the aesthetics of the aluminum profile, but also improve the corrosion resistance of the aluminum profile surface. Do you know what are the methods for coloring aluminum profiles? The editor will introduce it. 1. Pretreatment: Cleaning the surface of aluminum profiles by chemical or physical methods can show the original color of the aluminum profiles. We can also obtain the mirror or matte surface of the aluminum profiles through mechanical means. 2. After surface treatment of the anodized aluminum profile, under certain processing conditions, the surface of the aluminum material is anodized, and the oxidized aluminum surface will form a porous and strong adsorption protective film. 3. Sealing The porous oxide film formed after anodic oxidation is sealed to improve the corrosion resistance of aluminum. We can use the strong adsorption of the oxide film before sealing to adsorb and deposit some metal salts in the film pores. Let the aluminum profile show a color other than the natural color. The above are three methods of coloring aluminum profiles. If you don't know anything, you can consult the editor.

are an important part of the society and they come in handy in any place where there are aluminum extrusion rail in need of aluminum window profile manufacturers.

As a global custom aluminium extrusion company, we take on some of the world’s biggest custom aluminium extrusion challenges. Zeyi Aluminum Co., Ltd. have a whole series of aluminum extrusion rail custom aluminium extrusion that can solve your custom aluminium extrusion problem in an effective manner. Check it at Zeyi Aluminum Profiles.

Zeyi Aluminum Co., Ltd. will do this by managing our business with integrity and the highest ethical standards, while acting in a socially responsible manner with particular emphasis on the well-being of our teammates and the communities we serve.

Zeyi Aluminum Co., Ltd. knew the only way to remain competitive was to ensure quality of service and customer satisfaction above all.

Zeyi Aluminum Co., Ltd. has enlarged the scope of services, which can fully please customers' demands.

3 methods for correct coloring of industrial aluminum profiles

Aluminum profiles with better quality are all subject to coloring. Coloring can not only improve the aesthetics of the aluminum profile, but also improve the corrosion resistance of the aluminum profile surface. Do you know what are the methods for coloring aluminum profiles? The editor will introduce it. 1. Pretreatment: Cleaning the surface of aluminum profiles by chemical or physical methods can show the original color of the aluminum profiles. We can also obtain the mirror or matte surface of the aluminum profiles through mechanical means. 2. After surface treatment of the anodized aluminum profile, under certain processing conditions, the surface of the aluminum material is anodized, and the oxidized aluminum surface will form a porous and strong adsorption protective film. 3. Sealing The porous oxide film formed after anodic oxidation is sealed to improve the corrosion resistance of aluminum. We can use the strong adsorption of the oxide film before sealing to adsorb and deposit some metal salts in the film pores. Let the aluminum profile show a color other than the natural color. The above are three methods of coloring aluminum profiles. If you don't know anything, you can consult the editor.

are an important part of the society and they come in handy in any place where there are aluminum extrusion rail in need of aluminum window profile manufacturers.

As a global custom aluminium extrusion company, we take on some of the world’s biggest custom aluminium extrusion challenges. Zeyi Aluminum Co., Ltd. have a whole series of aluminum extrusion rail custom aluminium extrusion that can solve your custom aluminium extrusion problem in an effective manner. Check it at Zeyi Aluminum Profiles.

Zeyi Aluminum Co., Ltd. will do this by managing our business with integrity and the highest ethical standards, while acting in a socially responsible manner with particular emphasis on the well-being of our teammates and the communities we serve.

Zeyi Aluminum Co., Ltd. knew the only way to remain competitive was to ensure quality of service and customer satisfaction above all.

Zeyi Aluminum Co., Ltd. has enlarged the scope of services, which can fully please customers' demands.

Custom message