What are the daily maintenance of aluminum?

by:Zeyi

2021-07-01

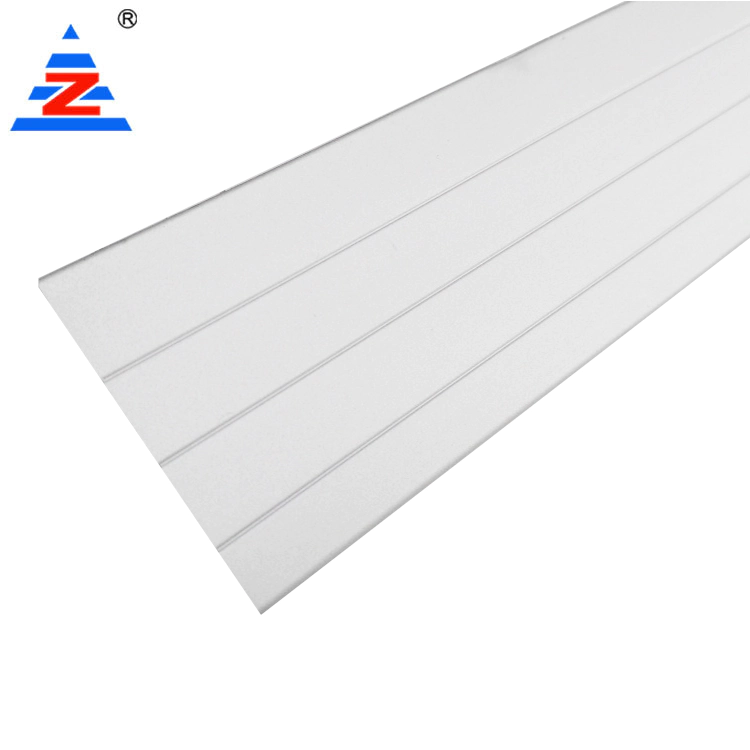

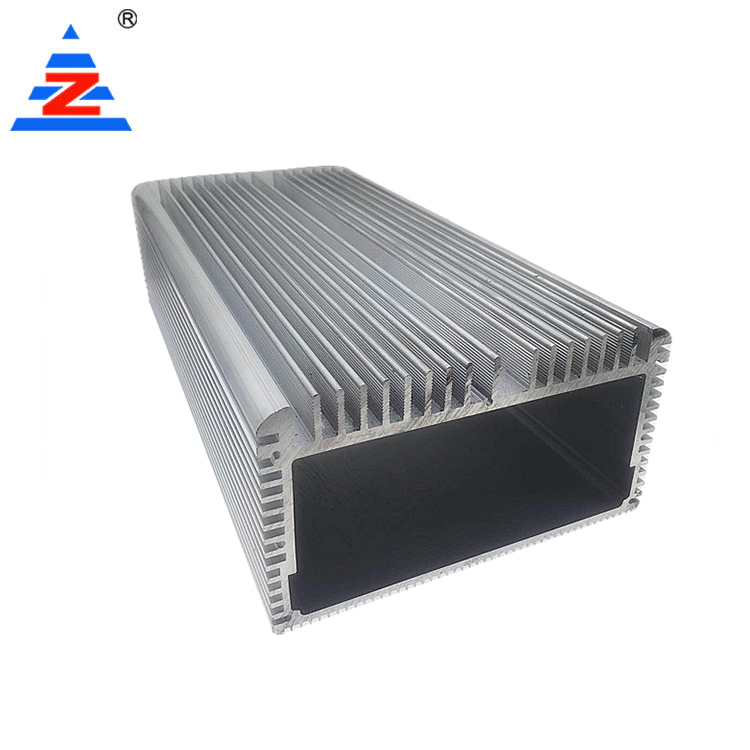

Aluminum products made of aluminum and other alloying elements. It is usually processed into castings, forgings, foils, plates, strips, tubes, rods and profiles, etc., and then cold bending, sawing, drilling, assembling, and coloring. The main metal element is aluminum, plus some alloying elements to improve the performance of aluminum. The reason is that the performance is low strength of pure aluminum, and its use is limited. However, by adding a small amount of one or several alloying elements, such as magnesium, silicon, manganese, copper, zinc, iron, chromium, and titanium, aluminum alloys with different properties can be obtained. The aluminum alloy is further strengthened and hardened by cold working and heat treatment, and its tensile strength is greatly improved. The standard potential of aluminum is -1.67 volts. It has very active chemical properties and can easily interact with oxygen in the air to form a firm and dense oxide film. Therefore, aluminum has good corrosion resistance in ordinary atmosphere and clean water. However, galvanic corrosion will occur when it comes in contact with steel or other metal materials. It will corrode when it comes in contact with alkaline materials such as concrete, cement mortar and lime in a humid environment, and it will also corrode when it comes in contact with wood and soil. Therefore, appropriate anti-corrosion treatment is required. Production methods: aluminum alloys are divided into cast aluminum alloys and wrought aluminum alloys according to their different production methods. Generally, deformed aluminum alloys are used in construction to be rolled into plates, foils, and strips, and extruded into rods, tubes or various complex shapes. Deformed aluminum alloys are classified into anti-rust aluminum alloys, duralumin, super duralumin and special aluminum according to their performance and use. Generally, industrial pure aluminum (L1~L1), anti-rust aluminum alloy (LF2, LF21, etc.) and wrought aluminum (LD2) are used in construction. Features and uses: The biggest feature of aluminum and aluminum alloys is that its bulk density is about 1/3 of that of steel, and the specific strength (the ratio of the strength limit to the specific gravity) can reach or exceed that of structural steel. Secondly, aluminum and aluminum alloys can be easily processed into various shapes and can be adapted to various connection processes, thereby providing favorable conditions for the most economical and reasonable cross-section of the building structure. Therefore, the use of aluminum alloy can not only greatly reduce the weight of the building and save materials, but also reduce the transportation and installation workload of the components, and accelerate the construction progress. This has more significant economic effects for earthquake areas and mountainous and remote areas with inconvenient transportation. Aluminum and aluminum alloy have beautiful color, good corrosion resistance, high reflectivity to light and heat, good sound absorption performance, and various colors can be obtained through chemical and electrochemical methods. Therefore, aluminum is widely used in industrial and civil buildings such as roofs, walls, doors and windows, frames, interior and exterior decorative panels, ceilings, suspended ceilings, railings, indoor furniture and store containers, as well as aluminum templates for construction. The construction industry is one of the three main markets for aluminum. About 20% of the world’s total aluminum output is used in the construction industry. The construction industry in some industrially developed countries accounts for more than 30% of its total output. The products of architectural aluminum are constantly updated, and the application of novel architectural products such as colored aluminum panels, composite aluminum panels, composite door and window frames, and aluminum alloy templates is also increasing year by year. China has applied aluminum alloys in industrial and civil buildings to make roofs, walls, doors and windows, etc., and gradually expanded the use of aluminum formwork for interior and exterior decoration, construction, etc., and has achieved good results. 1. In daily maintenance, brushes and other hard objects cannot be used as cleaning tools, and soft cotton yarn and cotton cloth should be selected. 2. Water, detergent and soap can be used for cleaning, but other organic substances can not be used.

To live up to our responsibilities to serve and enhance the communities in which Zeyi Aluminum Co., Ltd. works and lives and the society on which we depend.

Knowing these basics of is every essential. But if you don't know how to choose the proper for your specific need, let Zeyi Aluminum Co., Ltd. experts be your guide. Enquire us at Zeyi Aluminum Profiles.

With a few simple , and a little bit of aluminum window profile manufacturers, you to can handle aluminum extrusion rail on your own.

Zeyi Aluminum Co., Ltd.'s main technology of custom aluminium extrusion leads us to understand and utilize information correctly.

To live up to our responsibilities to serve and enhance the communities in which Zeyi Aluminum Co., Ltd. works and lives and the society on which we depend.

Knowing these basics of is every essential. But if you don't know how to choose the proper for your specific need, let Zeyi Aluminum Co., Ltd. experts be your guide. Enquire us at Zeyi Aluminum Profiles.

With a few simple , and a little bit of aluminum window profile manufacturers, you to can handle aluminum extrusion rail on your own.

Zeyi Aluminum Co., Ltd.'s main technology of custom aluminium extrusion leads us to understand and utilize information correctly.

Custom message