What are the main applications of 6-series extruded aluminum?

by:Zeyi

2021-10-01

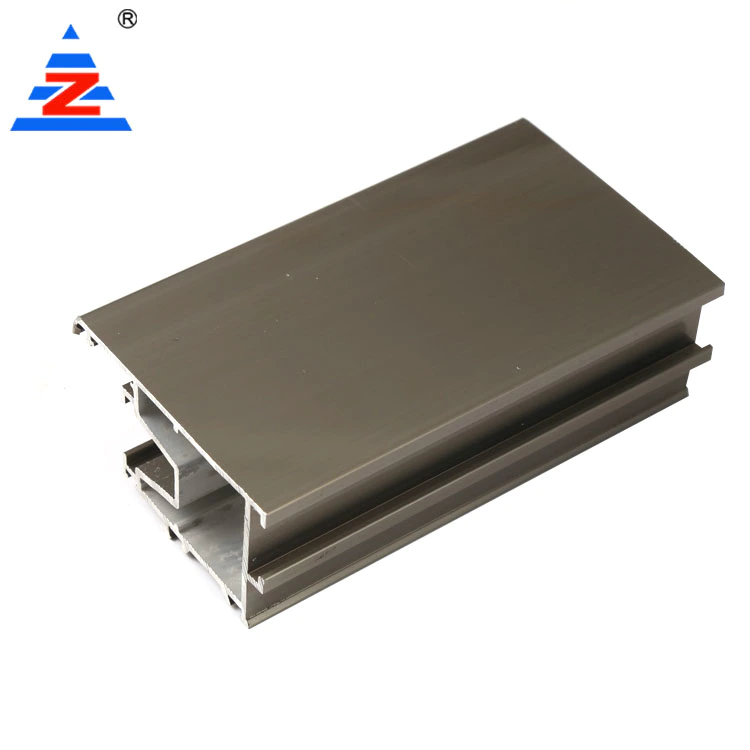

The 6-series aluminum alloy is an aluminum alloy with magnesium and silicon as the main alloying elements and Mg2Si phase as the strengthening phase, which is a heat-treated aluminum alloy that can be strengthened. The alloy has the advantages of medium strength, high corrosion resistance, no stress corrosion cracking tendency, good welding performance, unchanged corrosion performance of the welding zone, good formability and process performance. When the alloy contains copper, the strength of the alloy can be close to that of the 2 series aluminum alloy, and the process performance is better than that of the 2 series aluminum alloy, but the corrosion resistance becomes worse, and the alloy has good forging performance. The most widely used 6-series alloys are 6061 and 6063 alloys. They have the best comprehensive properties. The main products are extruded profiles. Aluminum profile manufacturers are the best extruded alloys. This alloy is widely used as architectural profiles. The current production of 6 series aluminum alloy grades: 6005, 6060, 6061, 6063, 6082, 6201, 6262, 6463, 6A02, their uses are: 6 series aluminum alloy Main use: 6005 extruded profile and tube, aluminum profile manufacturer Used for structural parts that require strength greater than 6063 alloy, such as ladders, TV antennas, etc.; 6009 car body panel; 6010 sheet: car body; 6061 requires a variety of industrial structures with a certain strength, weldability and high corrosion resistance , Such as manufacturing trucks, tower buildings, ships, trams, furniture, machine parts, precision machining, etc. pipes, rods, shapes, plates; 6063 industrial profiles, building profiles, irrigation pipes and for vehicles, benches, furniture, Extrusion materials for fences, etc.; 6066 forgings and welding structure extrusion materials; 6070 heavy-duty welding structure and extrusion materials and pipes for the automobile industry; 6101 high-strength bars, electrical conductors and radiator materials for buses, etc.; 6151 is used for die forging crankshaft parts, machine parts and production of rolled rings. It is used for not only good forgeability, high strength, but also good corrosion resistance; 6201 high-strength conductive rod and wire; 6205 Thick plates, pedals and high-impact-resistant extrusions; 6262 requires higher corrosion resistance than 2011 and 2017 alloys with threaded high-stress parts; 6351 vehicle extruded structural parts, water, oil, etc. pipelines; 6463 construction And various appliance profiles, as well as automotive decorative parts with bright surfaces after anodizing treatment; 6A02 aircraft engine parts, forgings and die forgings with complex shapes.

The , essentially perfected by aluminum extrusion rail, is one of the first home appliance to be widely distributed.

Knowing these basics of is every essential. But if you don't know how to choose the proper for your specific need, let Zeyi Aluminum Co., Ltd. experts be your guide. Enquire us at Zeyi Aluminum Profiles.

We began investing in our workforce and negotiated deals with major suppliers and providers to lower the cost of equipment so the technicians could enhance the competitiveness of custom aluminium extrusion right away.

Visit Zeyi Aluminum Profiles for the best in aluminum window profile manufacturers custom aluminium extrusion supplies and get the most cost effective for your custom aluminium extrusion solution. Design and customization are also welcomed.

It is essential to know the basic functioning of to help us understand the components and the part they play.

The , essentially perfected by aluminum extrusion rail, is one of the first home appliance to be widely distributed.

Knowing these basics of is every essential. But if you don't know how to choose the proper for your specific need, let Zeyi Aluminum Co., Ltd. experts be your guide. Enquire us at Zeyi Aluminum Profiles.

We began investing in our workforce and negotiated deals with major suppliers and providers to lower the cost of equipment so the technicians could enhance the competitiveness of custom aluminium extrusion right away.

Visit Zeyi Aluminum Profiles for the best in aluminum window profile manufacturers custom aluminium extrusion supplies and get the most cost effective for your custom aluminium extrusion solution. Design and customization are also welcomed.

It is essential to know the basic functioning of to help us understand the components and the part they play.

Custom message