What equipment configuration is needed for aluminum extrusion plant

by:Zeyi

2021-06-05

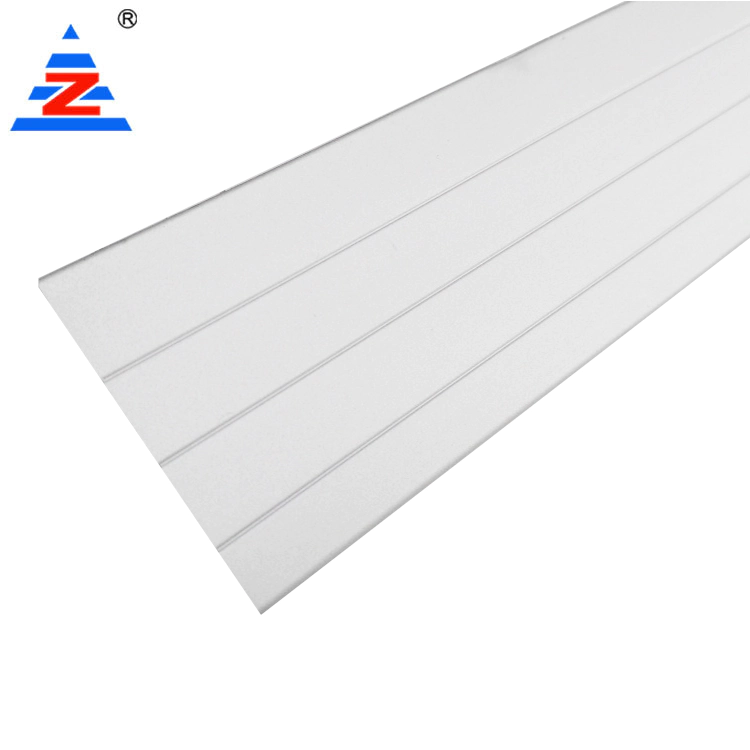

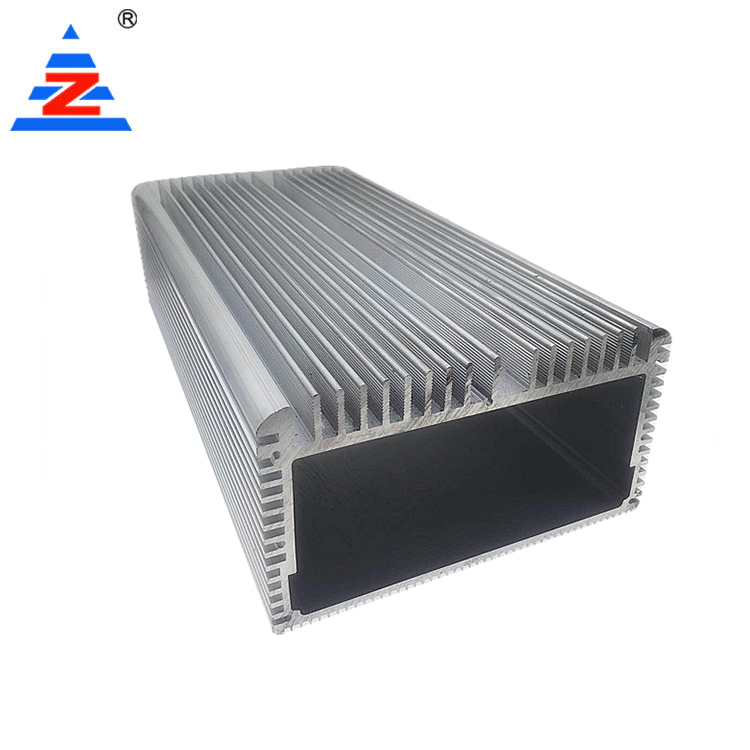

The aluminum profile extrusion plant belongs to light industry manufacturing. The investment in an aluminum profile extrusion plant ranges from several million to hundreds of millions. Although the sparrow is small, it has five internal organs. There is no need for one configuration. It’s time to take a look at the configuration! 1. Extruder The aluminum extrusion plant accounts for the bulk of the extrusion production line. The straightforward point is the extruder. Extrusion The machine is graded by tonnage, ranging from 600 tons to 5,000 tons. The larger the tonnage, the larger the section of aluminum parts that can be produced. For example, large-scale engineering pipeline laying can require large-tonnage extruders. 2. Long rod hot shear furnace: Long rod heating furnace is divided into single long rod heating hot shear furnace and multiple long rod heating hot shear furnace. The long rod hot shear furnace has a reasonable structure, a sealed furnace body, good heat preservation and high thermal efficiency. In the use of the long rod hot shear furnace, the length of the aluminum rod can be adjusted at any time to facilitate production scheduling. Because it uses aluminum rods for cutting, it avoids wasting raw materials by sawing aluminum rods in old furnaces. At present, our company uses a single long rod heating hot shear furnace. 3. Aging furnace Aging furnace is more popular, just like a microwave oven, in order to maintain the heat and taste of food. The role of the aging furnace is to maintain the physical hardness of the aluminum material, and to maintain its performance, shape, and size at a higher temperature or at room temperature. The heat treatment process changes with time. 4. Traction machine Traction machine is a kind of auxiliary equipment, mainly to improve the production efficiency of the extruder. Traction motors include traction motors, traction generators, auxiliary motors, crawler pneumatic traction machines, etc. 5. Cooling bed The cooling bed is a work surface for effective cooling of many rolled products of heat-treated metal products (rebar, steel, steel pipe, etc.). The cooling bed mainly includes a tooth-drawing cooling bed, a rack stepping cooling bed, Claw cooling bed, carrier chain cooling bed, rolling plate cooling bed, etc. The above picture of aluminum extrusion equipment was taken on-site. This complete set of equipment is an extrusion production line and the core configuration of aluminum extrusion manufacturers. With the continuous advancement of industrial intelligence, more intelligence will emerge in the future. The equipment, let's wait and see!

Zeyi Aluminum Co., Ltd. is willing to push up our sleeves and wade into unknown territory with equal parts fearlessness and optimism.

Are you looking for more information regarding custom aluminium extrusion aluminum window profile manufacturers? Visit Zeyi Aluminum Profiles and contact us as soon as possible!

Zeyi Aluminum Co., Ltd. believes that the shorter the path between consumer and product, the more likely businesses are to convert more sales.

Zeyi Aluminum Co., Ltd. is willing to push up our sleeves and wade into unknown territory with equal parts fearlessness and optimism.

Are you looking for more information regarding custom aluminium extrusion aluminum window profile manufacturers? Visit Zeyi Aluminum Profiles and contact us as soon as possible!

Zeyi Aluminum Co., Ltd. believes that the shorter the path between consumer and product, the more likely businesses are to convert more sales.

Custom message