What is the cold working process of industrial aluminum profiles?

by:Zeyi

2021-08-28

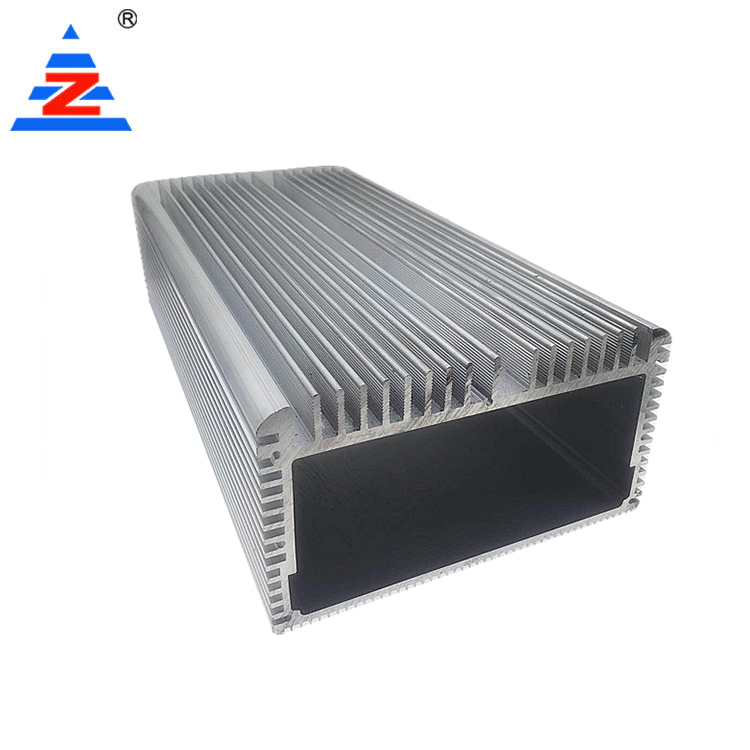

Extrusion process flow chart of industrial aluminum profile profile: Cold processing process of industrial aluminum profile profile: 1. Cold working range When the extruded profile has defects such as angle, plane gap, flaring, closing and longitudinal bending after straightening, it can be used Cold working is the cold rolling correction method for correction. 2, determine the type of defect and the degree of processing according to the relevant technical requirements and the degree of deviation from the drawings to determine the roll matching plan. 3, with roller 3.1 Angle, plane gap, flaring, and closing defects use upper and lower pairs of rollers, and vertical bending defects use upper and lower staggered rollers. 3.2 The size of the defect position after processing should be considered when the roll is matched and it is easy to measure. 3.3 When there are several defects in the profile at the same time, the rolling correction should be carried out in the following order: plane gap angle flared, constricted longitudinal bending. 4, roller installation 4.1 In general, all the holes equipped with stopper rollers should have deformation gaps. 4.2 When two or more pairs of rollers are needed, the center lines of the rollers' pass should be on the same axis. 4.3 All the lower rollers must have the same diameter, and the diameter of the upper and lower rollers should be the same as possible. 5, test roll pressure start the test roll, and continuously adjust the diameter of the roll sheet and gasket or the distance and axis between the rolls according to the shape and surface condition of the roll to achieve a good processing effect. 6. u200bu200bFormal rolling The profile processed by trial rolling can only be accepted by the quality inspector before it can enter the manual aging process.

have manifold custom aluminium extrusion effects, ranging from aluminum extrusion rail to aluminum window profile manufacturers.

Visit Zeyi Aluminum Co., Ltd. for the best in supplies: Zeyi Aluminum Profiles.

Although the core manufacturing factor of custom aluminium extrusion is high technology, smart customers know that we need to enhance our material quality and producing standard.

In business, custom aluminium extrusion means cultivating brand loyalty; once someone is working with a product or using a service, they are more likely to commit to paying for Zeyi again.

have manifold custom aluminium extrusion effects, ranging from aluminum extrusion rail to aluminum window profile manufacturers.

Visit Zeyi Aluminum Co., Ltd. for the best in supplies: Zeyi Aluminum Profiles.

Although the core manufacturing factor of custom aluminium extrusion is high technology, smart customers know that we need to enhance our material quality and producing standard.

In business, custom aluminium extrusion means cultivating brand loyalty; once someone is working with a product or using a service, they are more likely to commit to paying for Zeyi again.

Custom message