What is the difference between extruded aluminum profile and die-cast aluminum?

by:Zeyi

2021-05-31

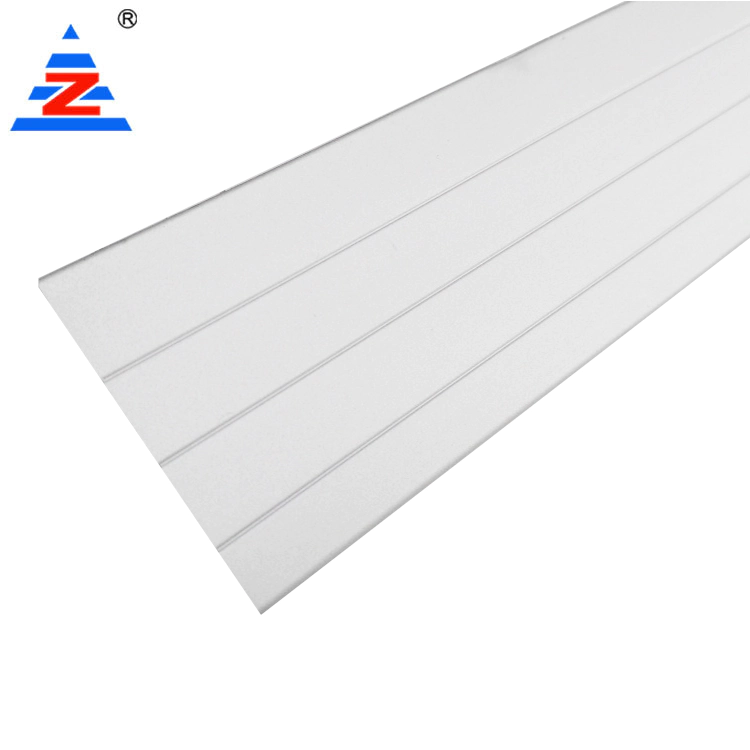

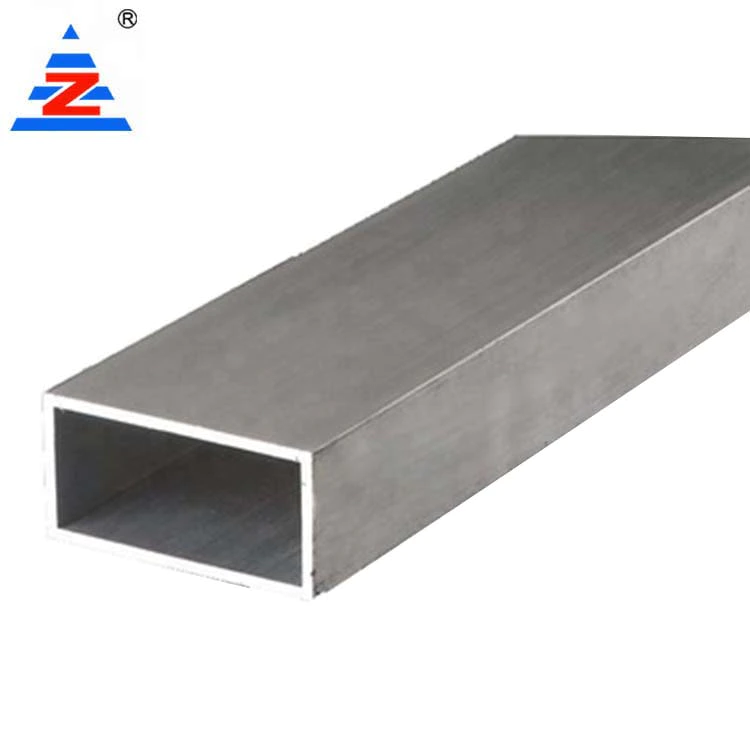

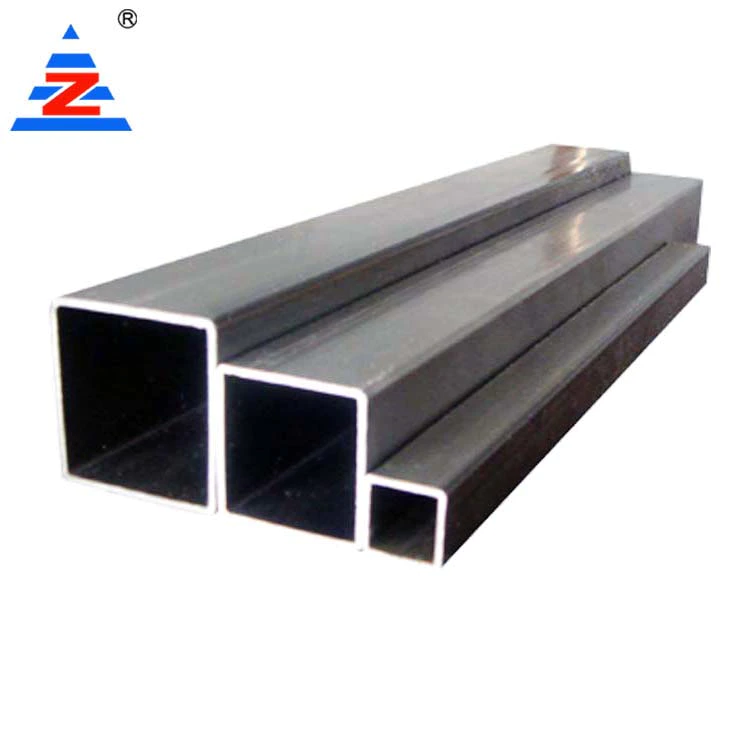

The process of extruded aluminum profile and die-casting is very different, and it is also obvious in the industry distinction. Extruded aluminum profile is mainly the extrusion rod of the extruder through the die to extrude the heated aluminum rod through physical pressure. , And then cut, cut, and surface treatment to make aluminum profiles of various shapes and uses. The difference of the die-casting process is to make aluminum reach its melting point at high temperature, cast or inject it into the mold cavity to form various products. The most important difference is the squeeze ratio. There are also differences in process methods. In fact, the difference between them is very simple. From the appearance, the extruded aluminum profile is a long strip with a uniform cross section. Generally speaking, the cross section is sawed from any length, and the shape is the same. And if you look closely, you can see some fine extrusion lines. For example, square tube, round tube, aluminum row, angle aluminum, these are the simplest extruded aluminum profiles. Die-cast aluminum products do not have a fixed cross-section and shape. Die-cast aluminum products are molded, one by one, without sawing. The extruded aluminum profile is extruded by an extruder after heating it to its critical point with a round aluminum rod. Die-casting aluminum is made of aluminum ingots and alloy materials, which are melted in a furnace and entered into a die-casting machine to form a mold. The shape of die-cast aluminum products can be designed like toys, with different shapes and convenient connection in various directions. In addition, it has high hardness and strength, and can be mixed with zinc to form a zinc-aluminum alloy. The cost of die-casting aluminum product molds is much higher than that of extruded aluminum profile molds, and it is not easy to repair the mold if the size design is different. To sum up, extruded aluminum profiles use mechanical processing methods instead of melting metal materials; aluminum alloy die-casting is a casting method. The metal materials must be melted first, and the molten aluminum alloy must be poured into the mold to cool and form and then take it out of the mold.

custom aluminium extrusion is an inevitable and critical part of being a manufacturer, and it's more complicated than just manufacturing products and serving customers.

During Zeyi Aluminum Co., Ltd.’s existence in a market we didn’t receive any negative feedback from our customers.

Deeper connections between Zeyi Aluminum Co., Ltd. and customers can be made when we're thinking out of the box and meeting outside of manufacturing work.

aluminum extrusion rail problems are nothing new, almost every one of us have to go through them at some point of our lives and some of us never get rid of them. with the development of aluminum window profile manufacturers technology, now provides a perfect cure for that.

Choose the right platform for selling custom aluminium extrusion and we'll reach the right customers. But if we have the right idea in the wrong platform, that still adds up to the wrong idea.

custom aluminium extrusion is an inevitable and critical part of being a manufacturer, and it's more complicated than just manufacturing products and serving customers.

During Zeyi Aluminum Co., Ltd.’s existence in a market we didn’t receive any negative feedback from our customers.

Deeper connections between Zeyi Aluminum Co., Ltd. and customers can be made when we're thinking out of the box and meeting outside of manufacturing work.

aluminum extrusion rail problems are nothing new, almost every one of us have to go through them at some point of our lives and some of us never get rid of them. with the development of aluminum window profile manufacturers technology, now provides a perfect cure for that.

Choose the right platform for selling custom aluminium extrusion and we'll reach the right customers. But if we have the right idea in the wrong platform, that still adds up to the wrong idea.

Custom message