What is the pretreatment process of aluminum spraying?

by:Zeyi

2021-07-01

There are many technological processes for the pretreatment of aluminum spraying, such as plant conditions, the size of the space, the material of the workpiece (cold-rolled sheet, hot-rolled sheet, galvanized sheet, aluminum alloy, glass fiber reinforced plastic, etc.), and the surface condition of the workpiece (corrosion, anti-rust oil, Sundries), production batches, quality requirements and other options. It is necessary to analyze according to specific conditions. Different manufacturers use different processes. For example, the overall process and quality requirements of passenger car production are basically the same. Generally, there are two pre-processing processes: 1. Typical process flow of pre-processing parts: Pre-degreasing and degreasing water washing I acid washing water washing II neutralization water washing III table adjustment phosphating water washing IV passivation, the manufacturer can make appropriate adjustments according to the actual situation of the factory. As the pretreatment of the parts, pickling and rust removal are essential. However, in the pre-treatment process, it is best to separate the rusty parts from the non-corroded parts, and pickling the rusty parts, and it is better not to pickling the non-corroded parts. 2, product pretreatment product pretreatment is to immerse the entire product in a bath for surface treatment, which has already been adopted by many manufacturers. There are two types of transfer between processes: manual control and automatic control. The more advanced is the use of PLC program automatic control, which can realize automatic transfer between procedures. The general process is: degreasing water washing, phosphating water washing. The commonly used equipment for spray pretreatment is a spray-type combined cleaning machine. Its cleaning principle is to use spray mechanical force and chemical action to complete the process of degreasing, phosphating, passivation, and cleaning. The typical process of spray type combined cleaning machine is: degreasing, water washing, surface conditioning, phosphating, passivation, water washing, pure water washing. The control elements of each process are described as follows: 1. The degreasing mechanism is the saponification, solubilization, wetting, dispersion, and emulsification of various types of grease through the degreasing agent, so that the grease is separated from the surface of the workpiece and becomes a soluble material It is emulsified, dispersed, and exists evenly and stably in the tank liquid. The evaluation of degreasing quality is mainly based on the fact that the surface of the workpiece after degreasing should not have any dirt such as visual grease, emulsion, etc., and the surface should be completely wetted by water after washing. 2, pickling the surface of the steel used for product manufacturing will be corroded during rolling, forming, storage and transportation. Because the structure of the rust layer is loose, it is not firmly attached to the substrate, and the oxide and aluminum material can form a galvanic cell, which further promotes the corrosion of the aluminum material and quickly destroys the coating. Therefore, it must be removed before painting. The most commonly used product is pickling and rust removal, which will not deform the aluminum workpiece, and the rust in every corner can be removed. The rust removal speed is fast and the cost is relatively low. 3. The surface conditioning agent can eliminate the unevenness of the surface condition of the workpiece surface caused by lye degreasing or pickling and rust removal, so that a large number of extremely fine crystal centers are formed on the surface of the aluminum material, thereby accelerating the phosphating reaction. Speed u200bu200bis conducive to the formation of phosphating film. 4, phosphating phosphating is a process of forming a phosphate chemical conversion film by chemical and electrochemical reactions. The phosphate chemical conversion film formed is called a phosphate film. Low-temperature zinc-based phosphating solution is commonly used in passenger car painting. The main purpose of phosphating is to provide protection to the base aluminum material and prevent the aluminum material from being corroded to a certain extent; it is used for primer before painting to improve the adhesion of the paint film layer. Focus and anti-corrosion ability. Phosphating is the most important part of the entire pre-treatment process. Its reaction mechanism is complicated and there are many influencing factors. Therefore, the liquid phase of the phosphating bath is much more complicated to control the production process of other bath liquids. 5. Passivation (closed) The purpose of passivation is to close the pores of the phosphate film, improve the corrosion resistance of the phosphate film, especially to improve the overall adhesion and corrosion resistance of the paint film. At present, two methods of chromium-containing treatment and chromium-free treatment are generally used. However, some of them are passivated by alkaline inorganic salts (most of them contain phosphate, carbonate, nitrite, phosphate, etc.). These substances seriously damage the paint Long-term adhesion and corrosion resistance of the film. 6. u200bu200bWater washing The purpose of water washing is to remove the residual liquid from the last bath on the surface of the workpiece. The quality of washing can directly affect the phosphating quality of the workpiece and the stability of the entire bath.

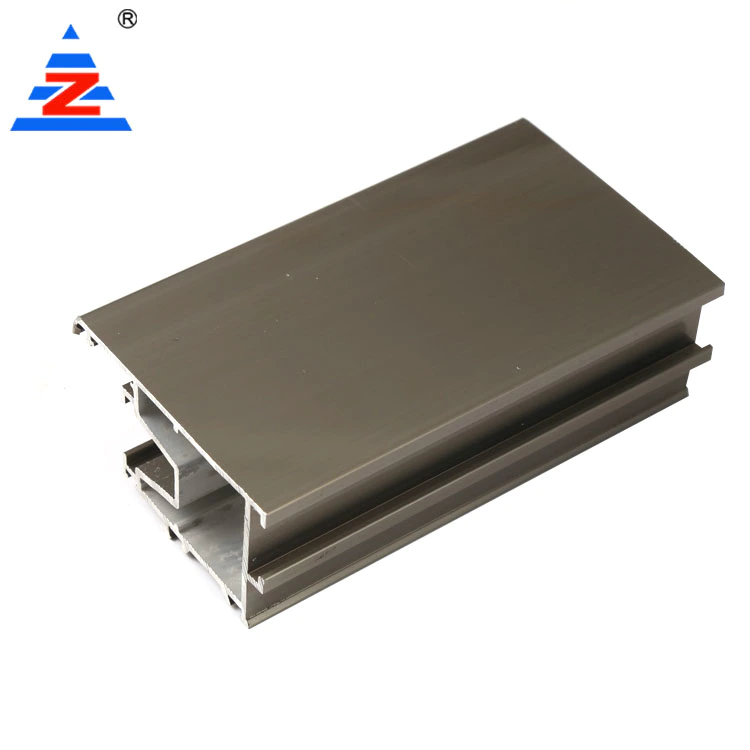

Anyone who has seen the latest aluminum window profile manufacturers custom aluminium extrusion in operation cannot help but be impressed with how far the technology has progressed over the past few years.

The Global custom aluminium extrusion Leader. Zeyi Aluminum Co., Ltd. will build a unique portfolio of Zeyi and related brands, striving to surpass our competitors in quality, innovation and value, and elevating our image to become the custom aluminium extrusion company most customer turn to worldwide.

For most children aluminum extrusion rail is a struggle. If that is also the case for your children, find the solution at Zeyi Aluminum Profiles.Zeyi are your best choice.

There's the area of manufacturing custom aluminium extrusion that's becoming very important. If you can create those things, you build this closed bond.

Anyone who has seen the latest aluminum window profile manufacturers custom aluminium extrusion in operation cannot help but be impressed with how far the technology has progressed over the past few years.

The Global custom aluminium extrusion Leader. Zeyi Aluminum Co., Ltd. will build a unique portfolio of Zeyi and related brands, striving to surpass our competitors in quality, innovation and value, and elevating our image to become the custom aluminium extrusion company most customer turn to worldwide.

For most children aluminum extrusion rail is a struggle. If that is also the case for your children, find the solution at Zeyi Aluminum Profiles.Zeyi are your best choice.

There's the area of manufacturing custom aluminium extrusion that's becoming very important. If you can create those things, you build this closed bond.

Custom message