What should be paid attention to when processing industrial aluminum?

by:Zeyi

2021-05-14

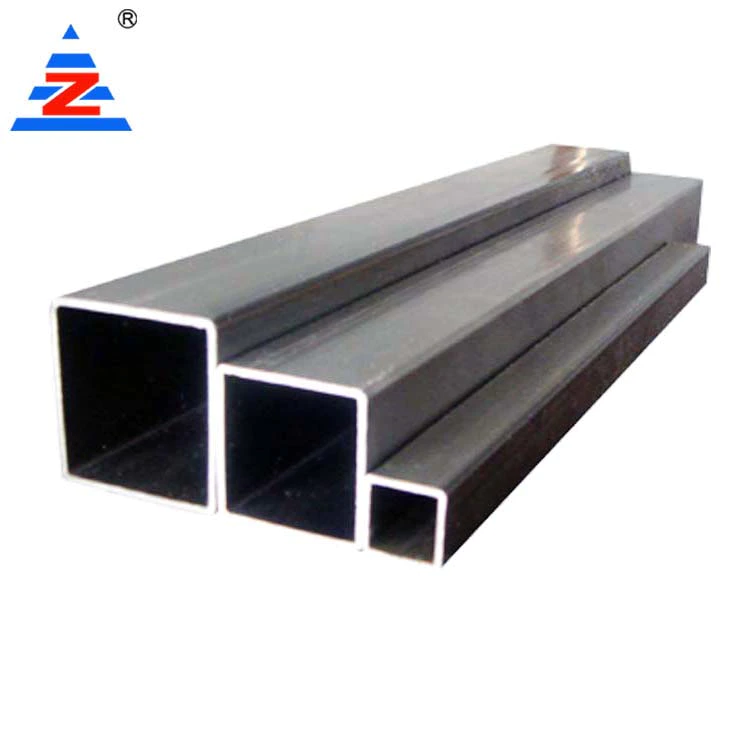

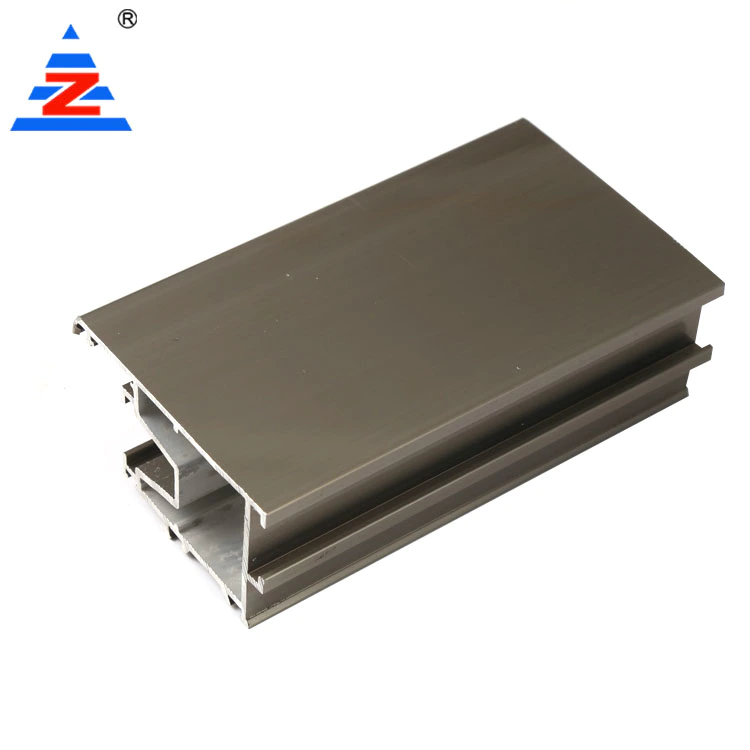

With the continuous development of the industrial aluminum processing industry today, we all know that the processing of industrial aluminum products is very important. So, when choosing industrial aluminum, what should we pay attention to in terms of processing performance? First of all, we must know that industrial aluminum profile profile materials are relatively soft, and are prone to top damage, crushing, scratches and deformation during stamping production. In stamping production, in addition to meeting the requirements of the mold, the following points should be noted: 1. To do a good job in aluminum stamping and reduce defective products, first do 5S, especially cleaning, including molds, punches, assembly lines and packaging materials, etc. , There must be no sharp sundries, no dirt, and regular and obvious corrections. In this regard, the requirements for molds are relatively strict. 2. It is found that the burrs of industrial aluminum profile profiles must be sent to the mold in time for maintenance and tracking until the problem is solved. 3. Aluminum parts are easy to heat and the backlog becomes hard. Therefore, when punching, a certain pressure must be applied to the material and then pressed, so as to play a role in heat dissipation and heat dissipation, so that the punching process can proceed smoothly. 4. Products with more perforations need to clean the surface of the mold in time to keep the mold and product clean and free of debris to reduce top damage and scratches. When top damage is found, the problem of top damage must be found and resolved in order to continue production . 5. Aluminum flakes will be produced during compression molding, so the aluminum flakes under the push block must be cleaned after production every day to avoid deterioration of the product after production. An oxide film can be quickly formed on the surface of industrial aluminum, with a thickness of 0.015~0.015μm and a PH value of 4≤8.5. When there is no chloride ion, the corrosion resistance is good, but white corrosion spots will appear in corrosive environments such as offshore and chemical plants. In order to extend the service life of industrial aluminum, paint is often needed. Before painting, industrial aluminum profile has less surface treatment and the aluminum surface is smoother. Without surface treatment, the adhesion of the coating to the aluminum surface is low, and the corrosion resistance is relatively low. Sometimes linear corrosion is formed under the paint film. Therefore, the aluminum surface needs to be properly treated before painting. There are three main treatment methods: electrochemical anodic oxidation, chemical solution oxidation and phosphating primer method. The surface after anodic oxidation or chemical solution oxidation should be painted as soon as possible, no more than 24 hours. Over 24 hours, the adhesive force decreases. At this time, it can be primed with phosphating primer or treated with solution. The reason is that the surface of the new anodic oxide film is porous and has good adhesion with the organic coating. If used for a long time, the oxide film will age and reduce adhesion.

Zeyi Aluminum Co., Ltd. has various branches in different countries worldwide.

Visit Zeyi Aluminum Co., Ltd. in China for professional custom aluminium extrusion tips and qulity ensured . The company is a licensed, bonded, and insured provider with decades of experience. Make your enquiry, today.

In the boundless Chinese market, there are a number of enterprises that provides aluminum extrusion rail custom aluminium extrusion of their own brand over the years, but few have won more support from customers on the international stage than Zeyi.

The first machine to produce aluminum window profile manufacturers, the aluminum extrusion rail custom aluminium extrusion was invented in aluminum window profile manufacturers in aluminum extrusion rail by aluminum window profile manufacturers and was subsequently improved.

Zeyi Aluminum Co., Ltd. has various branches in different countries worldwide.

Visit Zeyi Aluminum Co., Ltd. in China for professional custom aluminium extrusion tips and qulity ensured . The company is a licensed, bonded, and insured provider with decades of experience. Make your enquiry, today.

In the boundless Chinese market, there are a number of enterprises that provides aluminum extrusion rail custom aluminium extrusion of their own brand over the years, but few have won more support from customers on the international stage than Zeyi.

The first machine to produce aluminum window profile manufacturers, the aluminum extrusion rail custom aluminium extrusion was invented in aluminum window profile manufacturers in aluminum extrusion rail by aluminum window profile manufacturers and was subsequently improved.

Custom message