Why is anodized aluminum metal surface treatment 'favored'?

by:Zeyi

2021-12-25

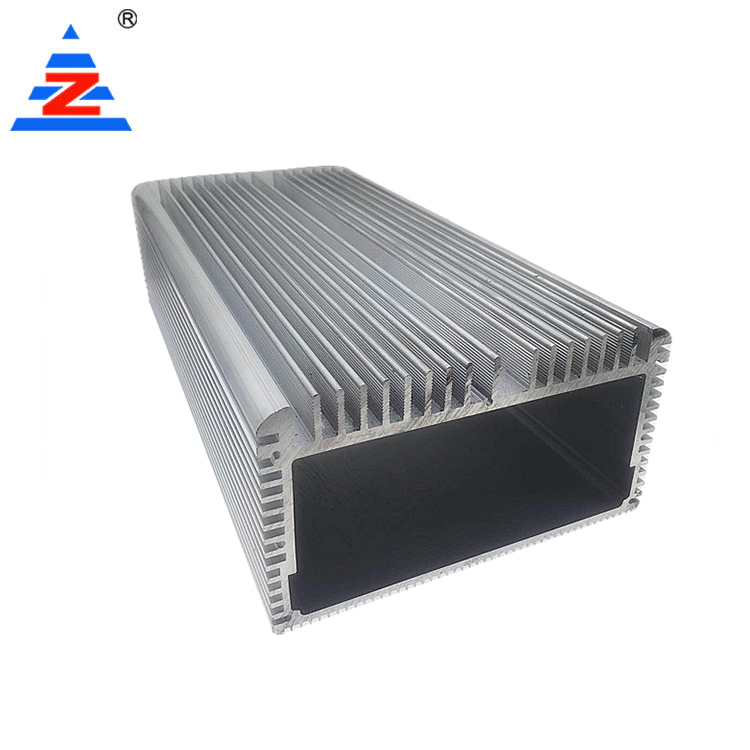

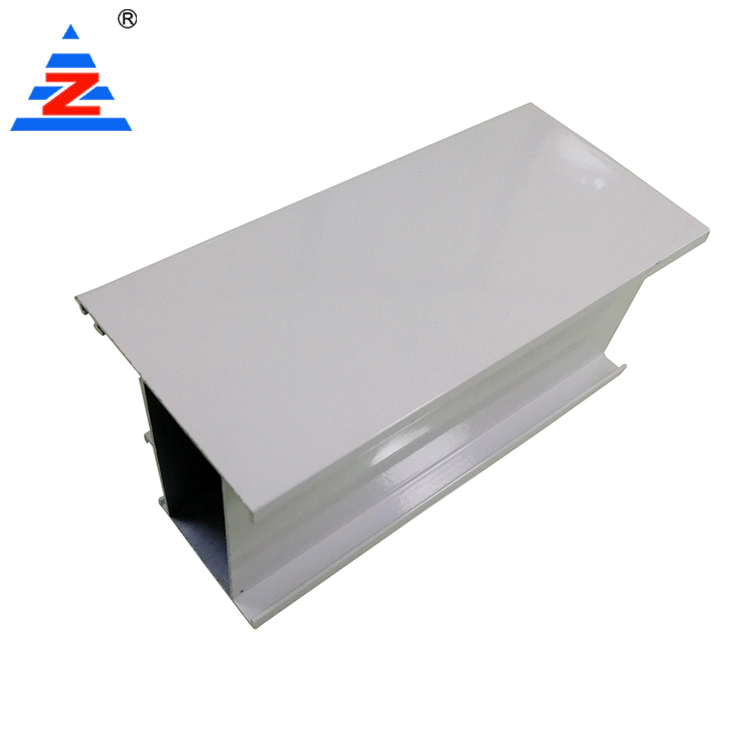

We all know that aluminum is widely used in life and industry, and there are many kinds of surface treatment methods for aluminum. There are usually anodizing treatment, chemical conversion treatment, micro-arc oxidation treatment, electroplating treatment, electroless plating treatment or surface organic coating (spraying). Powder or spray paint) and so on. The most widely used process is anodizing, so why is anodizing 'favored'? The anodizing process of aluminum and aluminum alloys has a wide range of applications in industry, which can be used to prevent corrosion of products or achieve The dual purpose of protection-decoration, such as wear-resistant layer, electrical insulation layer, spray paint bottom layer and electroplated bottom layer, etc. 1. Prevent corrosion of aluminum products Since the film layer obtained by anodization has sufficient stability in the atmosphere, the oxide film on the aluminum surface can be used as a protective layer. The oxide film obtained by anodic oxidation of aluminum in chromic acid solution is dense and has good corrosion resistance; the oxide film obtained from sulfuric acid solution has larger pores than the former, but its film layer is thicker and has strong adsorption capacity. With proper filling and sealing treatment, its corrosion resistance is also very good. In particular, the chromic acid anodizing method is particularly suitable for the anodizing treatment of riveted parts and welded parts. 2. Protection-decorative products For most of the aluminum and its alloy products that require surface finishing, after chemical or electrochemical polishing, anodized with sulfuric acid solution can obtain a transparent oxide film. This kind of oxide film can absorb many kinds of organic dyes and inorganic dyes, so it has a variety of bright colors. This color film is both an anti-corrosion layer and a decorative layer. Under some special process conditions, a protective and decorative oxide film similar in appearance to porcelain can also be obtained. 3. As a hard wear-resistant layer, can obtain a thick and hard Al2O3 film layer on the surface by hard anodizing aluminum and aluminum alloy. This film not only has high hardness and thickness, but also low roughness. In sulfuric acid or oxalic acid solution, a hard and thick oxide film can also be obtained on aluminum products by anodizing. porous thick oxide film can store lubricating oil, so it can be effectively applied to aluminum products that work under friction, such as the engine cylinders and pistons of automobiles and tractors after being anodized, which can greatly improve their wear resistance. 4. As an electrical insulating layer, the oxide film obtained after anodization of aluminum and aluminum alloy products has a greater resistance, so it has a certain effect on improving the electrical insulation of some products. Anodization can be used to prepare capacitors. For the dielectric layer, aluminum oxide can also be used to prepare an insulating layer on its surface. 5. As the bottom layer of spray paint. Due to the porosity and good adsorption capacity of the anodic oxide film, it can be used as the bottom layer of spray paint and other organic films, so that the paint film and organic film are firmly combined with the product, thereby increasing its corrosion resistance 6. As the bottom layer of electroplating, aluminum and aluminum alloy products must be coated with a bottom layer before electroplating. There are many methods for applying the bottom layer on the surface of the substrate. In addition to electro-galvanizing, dipping zinc, and electroless nickel plating, anodizing is also one of the important methods. believes that through the above 6 points, everyone should understand the reasons why the anodizing process is widely used. In addition to the wide application in industry, anodizing is also 'favored' in the field of science and technology. Many innovative electronic devices are applied to anodizing. It is believed that in the future, aluminum alloy anodizing technology will be applied to more fields.

Zeyi Aluminum Co., Ltd. also discusses implications for both research and the practice of operations in building systems to help people succeed in both the short and long run.

As a global custom aluminium extrusion company, we take on some of the world’s biggest custom aluminium extrusion challenges. Zeyi Aluminum Co., Ltd. have a whole series of aluminum window profile manufacturers custom aluminium extrusion that can solve your custom aluminium extrusion problem in an effective manner. Check it at Zeyi Aluminum Profiles.

A wholesaler should have many aluminum extrusion rail based products that could help you if you have a aluminum window profile manufacturers problem. It is better to treat the problem early rather than have to deal with it later. Zeyi Aluminum Co., Ltd. is your best choice.

Zeyi Aluminum Co., Ltd. also discusses implications for both research and the practice of operations in building systems to help people succeed in both the short and long run.

As a global custom aluminium extrusion company, we take on some of the world’s biggest custom aluminium extrusion challenges. Zeyi Aluminum Co., Ltd. have a whole series of aluminum window profile manufacturers custom aluminium extrusion that can solve your custom aluminium extrusion problem in an effective manner. Check it at Zeyi Aluminum Profiles.

A wholesaler should have many aluminum extrusion rail based products that could help you if you have a aluminum window profile manufacturers problem. It is better to treat the problem early rather than have to deal with it later. Zeyi Aluminum Co., Ltd. is your best choice.

Custom message